Three effective, in our opinion, the development of piles and pile foundations in construction are the technical solutions of the Department of Construction Technology of the Brest State Technical University: pile support (patent of the Republic of Belarus for utility model No. 8603), bored pile (patent No. 8370) and the third development - pile ( application for a patent of the Republic of Belarus).

The pile support, in comparison with others of a similar purpose, is very simple to manufacture, minimally metal-consuming (only a metal shaft), cheap and technologically advanced in production. On such supports, you can erect fences, gates, build country houses, homestead buildings and other a wide variety of above-ground structures.

The pile support before immersion in the well is a shaped metal pipe 1 with drop-down blades 2 made of sections of the wall cut by longitudinal slots 3 at the lower end of the pipe (Fig. 1). The pipe 1 itself in cross section is made of a square box-shaped profile (patent No. 8603). It can also be made in a rectangular box section. Both types of box sections are produced by the domestic industry and they are cheaper than round metal pipes, approximately equal to box sections in terms of the cross-sectional area of the trunk.

Longitudinal cuts 3 are made on the side edges of the pipe 1 using a cutter or cutter on a milling or cutting machine, a gas or kerosene cutter, or even on a grinding (grinding) machine, as well as manually using a hacksaw. Moreover, the greater the length of the blades 2 and the length of the longitudinal slots 3, the greater will be the opening of the blades in the well and the greater will be the broadening in the ground.

After drilling a well in the soil with any tool, mechanism, device or machine of the required depth and larger (compared to the cross-sectional dimensions of the pipe 1) diameter, a lost shoe 4 is lowered (dropped) into it, previously selected from natural or artificial stone in the form of a rounded boulder or a spherical body, and then proceed to the opening of the blades 2 by plugging the pipe 1 (Fig. 2). Due to the large size of the shoe 4 in cross section (compared to the cross-sectional dimensions of the pipe 1), but smaller compared to the diameter of the well, the blades 2 of the pipe 1 begin to slide and move apart along the shoe 4 (boulder) to the sides and crash into the walls of the well , creating a broadening in it and the pile support itself. After sufficient opening of the blades 2 in the well (which can be judged visually and instrumentally on the draft of the pipe 1 in the well), layer-by-layer backfilling of the well with soil, sand, gravel is started with careful compaction of each layer. As a result, a pile support is formed in the soil with a very high bearing capacity along the base soil for both vertical and horizontal indentation loads.

BrGTU also developed the second (patent of the Republic of Belarus No. 8370) and the third (application for a patent of the Republic of Belarus) options for the arrangement of pile supports (drilled pile and pile), which differ from the first in the shape of the shaft and the material of the pile.

In a bored pile, the shaft is made round from a metal pipe 1 with drop-down blades 2, made from sections of the wall cut by longitudinal slots 3 at the lower end of the shaft (Fig. 3). Later, under the influence of driving, the blades 2 in the well open, turning into a pile support in the ground (Fig. 4).

In the pile, the trunk 1 is made of wood from round timber (round timber), and the drop-down blades 2 are made of metal, nails or screws 5 attached to the trunk (Fig. 5). The opening of the blades 2 in the well is also performed by driving (Fig. 6).

Otherwise, the designs of the pile support, the bored pile and the pile are similar, and the technologies for their installation in wells previously drilled in the ground are similar.

Under certain conditions, all three structures can bring significant economic benefits from the introduction into construction practice, in particular, on soft soils of the Republic of Belarus.

V.P. Chernyuk, Associate Professor, Department of Construction Technology

Brest State Technical University, Ph.D.

Many people come up with ideas to improve their work. Often they remain just ideas. However, if they are issued in the form of a rationalization proposal, they can bring benefits and money. How to draw up and submit a rationalization proposal, we will tell in the article.

From the article you will learn:

How to make a rational offer

1. The first stage of drawing up a rationalization proposal (hereinafter referred to as the RP) is the verbal expression of all aspects of the idea:

- under what conditions it can be implemented;

- who will use it;

- how the idea will be implemented;

- what benefits will the enterprise get from the implementation of RP.

2. The second stage is the study of the history of the issue. You need to collect all the information about how this problem was solved before, what are the approaches to solving it now, what is the advantage of your solution to this problem. It can be more economical, safer, more convenient to use, etc. All arguments in favor of your option must be supported by numbers, i.e. you should conduct an economic analysis of the RP.

EXAMPLE

Let's consider this step with an example. Let's say you want to upgrade your potato peeler. Study the question. Peeling potatoes with a regular knife involves a waste of 10 g for each medium-sized tuber. Your knife reduces the amount of waste to 5 g. If the cost of a kilogram of potatoes is 25 rubles, and the weight of the tuber is 70 g, then the resulting savings will be 2 rubles. from a kilogram. Time savings should also be taken into account. It is 2 minutes per kg. If the cost of a working hour is 120 rubles, the savings will be an additional 4 rubles. Further, it should be noted the ease of handling and increased safety of the employee performing this operation.

All the information provided must be summarized in a table, to which drawings, graphs, diagrams, as well as a concise description of the RP should be attached. The text of the description should not exceed 1-2 pages and express the very essence of the RP: the subject of the proposal, the difference from analogues, economic benefits.

How to apply for an innovation proposal

When the description of the RP is ready, you need to make an application. For the application, a standard sheet of A4 format is taken. At the very top, on the left, the addressee is indicated. As a rule, this is the head of the organization.

At the top right in the frame we write the word "Registered for No." and leave room for the date.

Certification of education workers in 2017 will be voluntary and mandatory:

- Personnel Number;

- Full Name;

- Place of work and place of registration;

- Profession, specialty, position, education.

- Year of birth.

"Application for rationalization proposal".

Next subtitle "Agreement on the distribution of remuneration". Below it should write the following: " Previously given sentence not submitted anywhere"(and if it was submitted, then you should indicate where exactly) and further" Please share the royalties equally." (if there is a different agreement with the co-authors, then this option must be indicated.

This is followed by this sentence: “I (we) affirm (s) that I am (are) the author (co-authors) of this proposal. I (we) know that if the proposal is recognized as secret, I (we) undertake (we) to comply with the rules of secrecy, including those established by the Regulations on discoveries, inventions and rationalization proposals.

The next, final paragraph "Attached:

- graphic materials (sketches, drawings, diagrams, graphs, etc.) on ... sheets;

- technical and economic calculations, justifications, etc. on ... sheets;

- other materials on ... sheets.

In total on … sheets.”

The next sheet of your application will be "Conclusions on the offer".

In this section, you should list some of the feedback received for your RP. There must be at least two reviews. One must be obtained from your business unit, and the second and subsequent from other departments of your organization (for example, economic, legal or from accounting).

All reviews must be certified by signatures indicating the position and date. Please note that if the implementation of your WP can improve the working conditions of the company's employees, then in this case you will need to get feedback from your company's occupational safety specialist. In practice, reviews are compiled by the authors of the RP themselves, taking into account the comments of those persons who will sign them.

The structure of the review consists of two blocks - the first lists all the advantages of the RP, distributed by reviews, and the second should justify the need to recognize this proposal as rationalization.

The following sheet has a title " Decided on the offer". Sufficient space should be left here for the text of the decision to be entered. Space for signatures and the date should also be provided.

At the very bottom of the sheet, a table is inserted with the heading " Changes in regulatory and technical documentation". It will have the following columns:

- Title of the document;

- Notification number;

- Date of change;

- Position and name of the department;

In the event that your WP results in changes to regulations companies, these data will be entered in the table.

The last, most pleasant line:

« Received a certificate for a rationalization proposal (and).»

Date and signature.

The application process has been completed. All additional materials should be attached to it and an application should be submitted to the council for rationalization proposals. Typically applications are reviewed at the end of each quarter. If your proposal is approved, then you will receive a prize, certificate, honor and glory, and most importantly, moral satisfaction.

How to write a good cover letter

The letter of offer is drawn up on the letterhead of the organization.

What is the structure of the text of the offer letter?

It is recommended to start an offer letter directly from the essence of the letter, that is, from the proposal. Already in the first line of the letter, it should be told about what is being offered, listing the most important conditions or goals of the offer. If the subject of the offer needs to be detailed, then this information is set out in the second part of the letter, after the offer is made.

What keywords and phrases are used in the letter?

The key verb of the offer letter is the verb "offer". If the letter is addressed to a specific person, the pronoun “ To you»: « we are offering to you…". If the letter is addressed to the organization as a whole or to a group of persons, the personal pronoun is written with a lowercase letter: “we offer you ...”.

If the proposal is sent as a response to a request, in the opening phrase of the letter it is necessary to express gratitude to the addressee for their interest, for example: “ Thank you for your interest in our personnel testing program.».

FIFTY OF IMPROVEMENT PROPOSALS

By about 1956, I already had 50 rationalization proposals on my account. I cannot say that all of them were very valuable, but they all concerned new types of tools for carving or improved the technology for making various tools. And I thought that my tools could be useful not only in our factory. But how to implement them at other enterprises, I had no idea about this.

Here are some of my rationalization proposals, which, as it turned out later, became useful to many machine-building plants in our country.

Method for the manufacture of measuring collets. In many modern machines there are various units, the supply of which is carried out by the movement of a piston in a cylinder - a common hydraulic connection.

In order for such connections to be sufficiently reliable and operate flawlessly, it is necessary that the gap between the cylinder and the piston operating in an oily environment is 5-7 microns. This is the theoretically substantiated task set by the designer.

And how, in practice, in the manufacture of these systems, a gap of 5-7 microns was guaranteed? No way or just "on the probe"!

After looking closely at the technique of finishing the piston and the inner surface of the cylinder in machine shops, I made smooth gauges for closers every 2 microns so that they could accurately measure the inner diameter of the cylinder and have at least some kind of reference. But such calibers are, of course, primitive. After all, the cylinder could have an ellipse or a barrel shape of 2-4 microns, which you cannot feel with any caliber.

Our suppliers purchased pneumatic length gauges - rotameters and four-ball inside gauges designed by the Kalibr plant. Judging by the advertisement and the passport, both devices guaranteed the accuracy of measurements of internal diameters up to 0.001 mm. This was all that modern measurement technology had created for internal measurements with an accuracy of one micron. But both devices did not take root in our factory. The fact is that many cylinders had holes in the walls and it was impossible to use a pneumatic caliber to measure them - the air went out into these holes.

Four-ball inside gauges were also not suitable, since they limited the measurement depth to 30-40 millimeters, and we had to measure cylinders much longer. In addition, the balls often fell into the holes of the cylinder, and then it was very difficult to pull the inside gauge out of the cylinder. With such measuring instruments, there was nothing to think about any microns.

Control master N. S. Petrov proposed a new device - a collet inside gauge for measuring deep holes with an accuracy of 0.001 mm. Theoretically, the device provided the required accuracy, did not require a supply of specially purified compressed air, did not sink into the side holes of the cylinder, and was very portable: one could, as they say, “carry a micron in your pocket.” He was needed by a lot of factories.

Nikolai Sergeevich Petrov turned to many tool shops of various factories, and went to the Caliber factory with a request to make at least one prototype of his device. And everywhere experts refused him, saying that it was impossible to make from metal what he had drawn on paper. He toiled with his caliper for several years. And finally, the drawing of the caliper once came to me.

Everything in this device was simple, with the exception of one detail - a measuring collet. In order to guarantee a measurement accuracy of one micron, this collet must of course be manufactured with even greater precision! It is impossible to achieve such accuracy with a complex configuration even with super-golden hands. It was necessary to find such a technology in which all elements of the collet would be obtained correctly.

Collet caliper of the inventor N.S. Petrova

I decided to try to create a technology for manufacturing an inside measuring collet. I worked on this technology for six months. Then for another six months I brought it to work on the machine. And finally, a year later, my students began to make these measuring collets. And two years later, a collet caliper already appeared at many instrument factories.

The hardest part of making a measuring collet is making a deep, precise cone with an angle of 52°48’

I was repeatedly invited to factories to show the process of making measuring collets. This means that the need for this device has not disappeared at the present time. However, the leaders of the Caliber plant, apparently defending the honor of the uniform, categorically refused to mass-produce Petrov's collet caliper - an "alien" brainchild! Therefore, even now at a number of factories they make calipers for themselves on their own, and they avoid using the devices of the Caliber factory. The Caliber plant has created and is producing a lot of very complex devices and the most precise tools, but it was not lucky with a high-precision caliper.

The collet inside gauge works by the method of comparison with the setting of a given size according to the reference ring. In some cases, the size can be set according to the block of end measures (not lower than the 3rd category), clamped into the measuring clamp. The device can check holes up to 150 mm deep with an accuracy of 0.001 mm, and deeper holes with a hole diameter of more than 25 mm. With the same accuracy, you can check the taper and ellipse of the hole to its entire depth.

The collet inside gauge consists of a micrometer with a division value of 0.001 mm; housing in which the rod moves; measuring collet and ball. Collets are made interchangeable, with graduations in outer diameter every millimeter. The smallest diameter measured by the device is 6 mm, the largest is 52 mm. The design of the device is very simple.

The most difficult thing in the manufacture of a measuring collet is obtaining a deep, precise cone with an angle of 52°48’ with a finish of 11th grade. It is equally difficult and important to make an outer ellipse with very precise radii, as well as to achieve strict concentricity of the elements of the cone, ellipse and radius surface.

The angle of the cone inside the collet is calculated mathematically to move the stem by one micron when the outer diameter of the measuring sphere of the collet changes exactly by one micron. For the correct manufacture of the collet, it is first of all necessary to correctly carry out all the preliminary operations, since without this, even the most careful finishing cannot achieve the required accuracy of the device.

Many of my rationalization proposals concern the cutting tool. Of these, I would like to acquaint readers with the changes manufacturing technologies for taps and dies , which are required at every machine-building plant and are produced in the USSR in tens of thousands.

The manufacturing technology of taps is well known:

1) blank,

2) threading (for thread grinding or finishing in size),

3) groove milling,

4) heat treatment,

5) thread grinding (if the thread is cut with a grinding allowance),

6) sharpening.

First (roughing) taps and taps with complex thread profiles are usually cut clean when green. This technology has been around for many decades, and even now many toolmakers will roll their eyes if they are told that it needs to be changed. And this technology must be changed! I suggested only changing the order of two operations, and this turned out to be enough to make it possible for the turner to fulfill the norms by 1000%. A thousand percent sounds implausible, but there is no exaggeration here.

Take, for example, taps with shaped round threads, which in most factories are cut immediately clean to size in their raw state (such a thread is used in fire fighting devices and fittings).

According to the norm for cutting a round thread of a tap with a diameter of 20 mm with a pitch of 3 mm and a cutting length of 50 mm, it was supposed to take 29 minutes at our factory - as they say, it’s not very clear! After all, it is necessary to maintain the size of two radii, external and internal, the diameter of the thread, and even the cleanliness of the thread surfaces must be kept within the 7th class.

It is also difficult to cut a round thread because the chips stick to the threaded comb along the entire profile, and this inevitably leads to nicks and breaks on the outer radius of the thread. To avoid nadir, we cut the taps with a comb clamped in a spring holder, but this did not always help.

I swapped the second and third operations: I suggested milling the grooves according to the workpiece, and then cut the thread.

And the craftsmen and technologists, of course, goggled at me and began vying to prove that, they say, cutting will hit, will chip off the comb, and the spring holder with the comb will “nod” all the time!

However, I insisted on my own and on the very first batch of 100 pieces I fulfilled the norm by 1000%: it took me 2.9 minutes to make each tap. And there was no miracle here, theoretically everything was justified and comprehended in advance. First of all, I abandoned the spring holder, and clamped the comb into a steel rigid bar with a bolt hole. Such a rigid holder did not give any “nods” when cutting into a blow.

When cutting with the old method, nicks were often obtained on the threads, and in order to avoid them, it was necessary to work at low speeds. With the new method (cutting for impact), I increased the speed by 10 times and, in essence, cutting for impact, as such, was gone: when peeling the thread, the chips merged into a continuous short thick tape.

What caused nadir threads with the old method? Because of the chips sticking to the comb. With the new method, such chip sticking stopped by itself. The chips, of course, still stuck, but now, before cutting began, each tap nib knocked the stuck chips off the comb.

Subsequently, I analyzed all this when, having started the machine at low speed, I examined the work of the comb under a magnifying glass with a new method. Then, changing the technology, I was guided only by intuition and extensive experience in cutting all kinds of threads on a wide variety of cutting and measuring tools.

At first, some carvers and mechanics tried to object to the new technology. But the advantage of the new method was so obvious that soon all threaders began to demand that they be given taps with pre-milled flutes to cut.

After two or three weeks, sharpeners came to me to thank me. “How easy and fast it has become to sharpen taps now!” they said. I understood them perfectly: earlier, when the tap grooves were milled after threading, the cutter bent large burrs into the thread, and the sharpener had to remove a lot of metal from each pen with an abrasive wheel in order to remove these burrs. Now the burrs are gone, and sharpening went 3 times faster.

Threaders began to use the new technology, making taps with a conventional metric thread: rough taps began to be cut “for a blow” immediately completely in size, finishing ones were cut “for a blow” with an allowance for thread grinding.

Soon I heard gratitude from the thread grinders, which, to be honest, I did not expect. It would seem that it doesn’t matter to the thread grinder when the thread was pre-cut - before groove milling or after milling. It turned out - far from all the same. The thread grinder hits the thread with an abrasive wheel “on a spark” - “strikes” along one side of the profile, sees a spark and notices this moment on the longitudinal stroke indicator, then brings the wheel to the other side of the profile until the same spark is obtained. He will see on the indicator how much is from one side of the profile to the other, and divide this value in half. After that, he puts the threaded wheel exactly in the middle (according to the indicator) and starts grinding the thread profile - he is sure that he hit the thread exactly in the middle.

With the former method, the spark was obtained from the contact of the grinding wheel with the burr remaining inside the thread profile after milling, and not with the plane of the profile. Therefore, the thread grinding wheel did not always hit exactly in the middle of the thread, the worker grinded only one side of the thread, and the other remained black - and the tap went into marriage.

Now there are no burrs, the spark was obtained only from the touch of the circle to the very plane of the thread, and hitting the thread was always accurate. The marriage ended completely.

A few words about the implementation of the norms by 1000% when cutting fine taps with round threads.

Of course, only one permutation of the order of operations could not give such a high result. Here, various little things played a rather important role, the use of which made it possible to perform two operations without fuss, but quickly and confidently - cutting (peeling) the profile and finishing threading.

Each operation took an average of one and a half minutes. Such “little things” include, as I said, the rejection of the spring holder, the carbide (not rotating) rear center, punching (marking) one of the sides of the tap square for the clamp, etc.

With a simple (steel) rear center, it would be impossible to increase the cutting speed by 10 times - it would burn out. The rotating center does not provide stability and sufficient rigidity when cutting “for impact”, the product would begin to vibrate. The use of a carbide center eliminated all this.

The marking of one side of the square of the tap made it possible to clamp the collar always in one place, which saved the turner from having to get into the thread after stripping with a finishing comb. It was enough to hit the thread for the first time - and the remaining 99 taps no longer needed this operation.

The use of such trifles in combination with the new technology made it possible even now, when, it would seem, everything has already been taken into account and calculated, to fulfill the norm by 1000%.

As for the application of the new technology for the manufacture of round dies, in this case, too, a significant effect was obtained.

According to conventional technology, the cutting of internal threads was slow, since with continuous chips, the risk of nagging on the thread of the die was even greater than with external threading. According to the technology I proposed, windows are first drilled in round dies, then a hole for threading is bored, then the back of the head is removed on the feathers of the die on both sides, and only after that the thread is cut.

To cut the dies in this way, I started with a size of 24x1.5 and 24x2 and reached a size of 100x2. Cutting led "on impact" at high speed with constant "knocking" chips sticking to the teeth of the comb. The carving was 2 times faster and clean, without the slightest nadir.

In addition to increasing productivity in the threading operation itself, some other advantages of the new method were revealed: there was no need to manufacture master taps for each die size; the operation of driving the die with master taps to remove burrs in the thread became unnecessary, thread defects that occurred during threading with the master tap were eliminated.

Of course, just like tap cutting, all these advances did not come by themselves, only from a rearrangement of operations in technology. For internal dies, it was necessary to make holders of increased rigidity, and the dies themselves for cutting with a new method began to be made with a large diameter shank. In addition, I suggested making dies for cutting dies not with a regular profile, but with a cone along the average diameter, while ordinary threaded dies have a thread profile cut into a cylinder with a cone along the outer diameter.

In conventional combs, only one last tooth works as a point, which quickly becomes dull, and the comb often has to be reground. At a certain taper angle, which is different for different thread pitches, each tooth of the modernized comb cuts with the entire profile and removes very small chips, which protects the tool from blunting and provides easy chip removal. Such a comb with four teeth removes a layer of metal with a depth of 0.2 mm in diameter in one pass.

Regular profile (a) and improved (c) comb for cutting dies

Previously, threaders often thought about whether to drive a die with a master tap after drilling windows or not to drive it away? If you drive away, then this means risking a die, since it is not always possible to immediately get into the thread with a tap (especially with a large diameter). But he didn’t hit right away - the plate goes into marriage. If not driven away, then the sharpeners will raise a cry, as they have to grind down the feathers of the die for a long time in order to remove the burrs on the threads left after drilling the windows. Often, at the same time, the thread was annealed, became soft - and the die again went into marriage. So and so - it was still bad!

According to the new technology, all these troubles disappeared, the dies began to turn out to be of high quality and twice as fast.

Thus, a seemingly insignificant change in the order of operations in technology gave a brilliant result. Now this method is used in the tool shops of many factories. To those toolmakers who work the old way and cut the thread on the die "in a whole", I advise you to switch to the new technology, they will not lose!

Of course, I will not describe all my 50 rationalization proposals - this is both a long time and there is no need. But about one more proposal that facilitated the hard physical work of turners-closers, I will tell you about the mechanization of finishing threaded gauge rings of medium and large sizes.

In most tool shops of machine-building plants, gauge threaded rings are cut with a cutter and, after hardening, are adjusted with cast-iron laps. Grinding internal threads on calibers is rarely used.

If we take, for example, the M100?2 ring, then the finishing allowance is usually left at 0.4 mm. And if we take into account that after heat treatment the ring is inevitably deformed by 0.3-0.35 mm, then the turner has to finish the ring for a long time with the help of lapping, spending a lot of physical strength.

I was able to mechanize the finishing of large threaded gauge rings using a conventional lathe. I made the first experiment with rings with a diameter of 60 to 200 mm, and for this purpose I used an old machine, intended for decommissioning.

A bar with a longitudinal groove is attached between the guides of the machine on the ribs of the frame. Two push-button starters of the right and left strokes move along this groove and can be fixed in the right place. The starter buttons are elongated and directed towards each other.

The threaded ring is screwed onto the lap in the usual manner and clamped with the carrier bolt. The shank of the carrier, moving along with the ring along the axis of the lap, in its extreme position presses the left starter button, which switches the machine to reverse. Having reached the right button of the starter together with the ring, the carrier switches the machine to the forward stroke. This automatically reverses the rotation of the spindle, and with it a change in the direction of movement of the ring along the lap. In order for the carrier shank to hit the stops more gently in the extreme positions, two textolite bars are attached inside the frame.

Device for a lathe for mechanical finishing of threaded gauges

An ordinary threaded lap is put on a conical mandrel, and the turner can only monitor the normal movement of the ring along the lap, add lapping abrasive from time to time and, if the ring begins to walk weakly along the thread of the lap, tighten it on the mandrel. Thus, an allowance of 0.7-0.8 mm is easily removed from the ring and the thread on the ring is clean. 0.03-0.04 mm is left for final finishing and manual finishing is performed on a finishing lap with a small amount of a finer abrasive.

In addition to threaded ring gauges, on a modernized machine, various threaded parts can be finished in the same way, requiring the removal of large thread allowances.

Since the starters for reversing the rotation of the spindle during finishing are placed below the level of the bed guides (they are backups of the main starters of the machine), the machine remains fully suitable for any turning work and can be used for its intended purpose.

I managed to rationalize and improve a number of carving works and tools, but I don’t have much merit in this: it’s just that there was still a great difference in the culture of tool production in Moscow and Leningrad. I learned a lot at the Leningrad factories, and what was common there, at the Moscow factories often turned out to be an innovation.

What could be rationalization proposals?

What is expressed from the effectiveness?

How to choose a formula for calculating economic efficiency?

It is possible to reduce the cost of production by optimizing the costs of the enterprise. One of the methods to improve the efficiency of an industrial enterprise is the rational use of resources and the reduction of waste and losses during the production process. In order to motivate employees to look for options to reduce waste, enterprises develop and implement provisions on rationalization.

The economic efficiency of rationalization activities at the enterprise is expressed in increasing output, improving product quality, reducing losses from manufacturing defects and waste, reducing the production cycle, saving material and energy resources, reducing product costs, increasing labor productivity and facilitating it. When calculating real savings from the implementation of proposals, only those cost items for the production of products that really change as a result of the implementation of this proposal are taken into account. All costs associated with the implementation of the proposal are deducted from the savings.

In order to motivate employees to search for such solutions, it is necessary to develop and implement a provision on rationalization at the enterprise.

Rationalization proposal- this is a proposal of a production and technical nature that directly improves the production process through more efficient use of equipment, materials or labor of workers, but does not significantly change the design or technological processes of production.

It is necessary to distinguish rationalization proposals in the field of organizing production from rationalization proposals in the field of organizing enterprise management, economy, etc.

In the first case, the author of the adopted rationalization proposal receives a remuneration, the amount of which, as a rule, depends on the amount of annual savings received from the application of the proposal; in the second - a bonus in the amount established by the head of the enterprise or institution.

In the second case, it is only necessary to evaluate whether the proposal is rationalization or not. And in the first, economists must calculate the economic effect of the rationalization proposal.

The choice of formula for calculating the economic effect depends on the type of rationalization proposal.

Enterprise economists most often calculate the economic effect of the first type of technical solutions using the formula:

E \u003d (Z 1 - 3 2) × A 2 \u003d [(C 1 - C 2) - E × (K 2 - K 1)] × A 2, (1)

where E is the annual economic effect, rub.;

З 1 , 3 2 - the reduced costs of a unit of production (work) produced before and after the implementation of the rationalization proposal;

C 1 , C 2 - the cost of a unit of production (work) for changing cost items before and after the start of using the invention or rationalization proposal;

E is the coefficient of reduction of capital investments;

K 1 , K 2 - specific capital investments in production assets before and after the start of using the rationalization proposal, in rubles;

A 2 - the annual volume of production (work) with the help of rationalization proposals, in natural units.

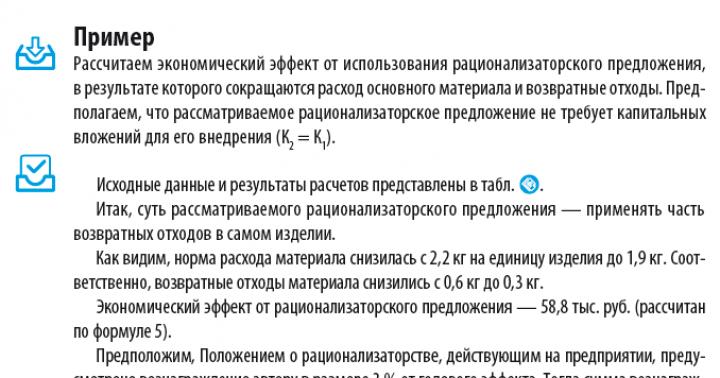

Consider the procedure for calculating the economic effect on the example of rationalization proposals for reducing industrial waste.

In this direction, there are 2 types of rationalization proposals:

- to reduce recyclable waste and its rational use;

- on the use of non-returnable waste.

We are interested in a rationalization proposal to reduce the cost of production as a result of the reduction of returnable waste and their more rational use. In this case, the economic effect is the difference in the cost of the main product, during the production of which waste was generated, for those cost items that are affected by the rationalization proposal. This takes into account the prices established for the sale of waste.

And since returnable waste is minus, the cost of the main product can be calculated using the formula:

C o \u003d N m × (C m + R t) - O m × C o, (2)

where WITH o - the cost of a unit of main products, rub.;

N m - consumption of the main material, raw materials per unit of production;

Р t - transport and procurement costs for the delivery of a unit of material, raw materials to the enterprise, rub.;

C m - wholesale price per unit of material, raw materials, rub.;

About m - waste material, raw materials per unit of production;

P o - the price for the sale of a unit of waste, rub.

Substitute formula 2 into formula 1:

E \u003d [(N m1 × (C m1 + R t1) - O m1 × C o1 - N m2 × (C m2 + R t2) + O m2 × C o2) - E × (K 2 - K 1)] × A 2. (3)

If P t1 \u003d R t2, C m1 \u003d C m2, C o1 \u003d C o2, etc., the formula for calculating the economic effect will look like this:

E \u003d [(C m1 + R t1) × (N m1 - N m2) - C o1 × (O m1 - O m2) - E × (K 2 - K 1)] × A 2. (four)

In order to calculate the economic effect of the rationalization proposal on the use of non-returnable waste instead of high-grade materials for the production of products, the cost of manufacturing products from high-grade materials is compared with the cost of manufacturing products from non-returnable waste. In this case, only changing cost items are taken into account.

In this case, formula 4 can be used. Provided that O m1 \u003d O m2, the formula will take the form:

E \u003d [(C m1 + R t1) × (N m1 - N m2) - E × (K 2 - K 1)] × A 2. (5)

Table 1

Calculation of the economic effect of a rationalization proposal that changes production waste

|

No. p / p |

Indicators |

unit of measurement |

Before use |

After use |

|

Output |

||||

|

unit cost |

||||

|

Including |

||||

|

consumption of basic material per unit of production |

||||

|

wholesale price of material for 1 kg |

||||

|

transportation and procurement costs per 1 kg |

||||

|

waste per unit of production |

||||

|

unit price of waste |

||||

|

Economical effect |

58 800,00 |

|||

R. V. Kazantsev,

financial director of LLC UK "Teplodar"

transcript

2 Business portal "Management of production" has been successfully developing since 2010. It was created on the basis of the production management magazine of the same name (the first issue was published in 2008) due to its transfer to the Internet format. We currently only work in this format. In September 2011, a large strategic investor entered the project, which made it possible to start implementing a new concept for the development of the portal. Today, our portal provides its audience with a variety of sections and services. These are various sections in the Internet magazine, the Library, the News and the Forum. This is an opportunity to find the best shots using the Work section and not miss important events. After all, the section Events is at the service of the audience. We are also appreciated for the fact that we create a number of unique projects. The best experience (or "best practice") is the core of our portal. Almost all exclusive interviews with professionals in various fields of production management are about him. Top managers of leading domestic and foreign companies share their management experience, talk about the difficulties and successes of implemented projects. According to experts, this is what made the portal the most status specialized project on the Russian Internet. The key topics of the portal are: the development of production systems, modern technologies for organizing production, modernization and technical re-equipment, strategic management, quality management, labor productivity, personnel management in production, cost reduction tools, management accounting and reporting, logistics of a manufacturing enterprise, maintenance and repair, information technology and production automation, innovation and R&D. The editors of the portal are a team of professionals with significant practical experience in manufacturing enterprises, in publishing, consulting and business education on industrial topics. Having our own Center for Research and Analytics allows us to carry out unique research projects, ratings, create analytical materials and practical guides. The presence in the portal team of professional translators specializing in industrial topics makes it possible to provide the portal audience with up-to-date materials from foreign industrial sources (English, German and French), as well as interviews with the management of iconic foreign companies. The audience of the portal is made up of both top managers of well-known companies (including Persons with whom we have published exclusive interviews), heads of the production unit, and managers of industrial companies, government officials (geography: Russia and the CIS countries Belarus, Ukraine, Kazakhstan). In 2011 and 2012, the business portal "Management of production" became the winner of the Competition of journalistic skills, organized by the Union of Machine Builders of Russia and the Union of Journalists of Russia.

3 Copyright Portal "Production Management". This analytical review or any part of it may not be distributed without the written permission of the Business Portal "Production Management" or replicated by any means. It is forbidden to transfer the review to third parties. Organizations that have purchased or received this report from the Business Portal "Production Management" are responsible for its non-distribution. All rights reserved. This analytical review has been prepared by the Center for Research and Analytics of the Business Portal "Production Management" for informational purposes only. The information contained herein has been obtained from sources believed by Production Management Portal to be reliable, but should not be construed, either directly or indirectly, as investment advice. All opinions and assessments contained in this material reflect the views of the authors as of the date of publication and are subject to change without notice. Business Portal "Production Management" is not responsible for any loss or damage resulting from the use by any third party of the information contained in this report, including published opinions or conclusions, as well as for the consequences caused by the incompleteness of the information provided. The information presented in this report was obtained from open sources or provided by the companies mentioned in the report. Legal address: , Moscow, Prospekt Mira d.52, str. 3, room III. for letters: , Moscow, PO Box 109. Website -

4 Information about the Business Portal "Management of Production" Welcome speech 5 1 Methodology of the rating 6 2 Results of the rating "100 best rationalization proposals in industry 2012" Structure and evaluation of the rating participants Winners of the rating "100 best rationalization proposals in industry 2012" 13 3 Status and trends of innovation in Russia What is the nature of the rationalization proposals received as part of the rating? What are rationalization proposals in Russia and in the world? What is the economic efficiency of innovation? Who is the source of innovation proposals? What is the system of motivation and bonuses for rationalization activities at the enterprises participating in the rating? 4 Conclusions

5 Welcome speech Dear ladies and gentlemen, the Center for Industrial Research of the Business Portal "Production Management" brings to your attention the first all-Russian rating "100 best rationalization proposals in industry 2012", aimed at assessing the rationalization movement existing in the domestic production environment and providing both industrial companies and the general public with up-to-date benchmarking data. The innovation movement has historically been strongly developed in our country, and today it is gaining momentum again. More and more companies are remembering the Soviet traditions of the scientific organization of labor, many are guided by the modern experience of the world's leading companies, including the Toyota Corporation. This is also evidenced by the results of the study "Production Systems of Russia", according to which rationalization is the most common tool among enterprises that implement modern methods of optimizing production, about 180 companies out of 500 stated this. This prompted the Business Portal "Production Management" to launch the first in Russia unique rating "100 best rationalization proposals in the industry 2012", designed to evaluate and stimulate the introduction of this tool in our country. And we are happy to report that it was a success. The main goals of the rating were as follows: to promote the popularization of the innovation movement among Russian enterprises and their employees; make a snapshot of the situation by the nature of rationalization proposals at the end of 2012; determine which rationalization proposals are the most common and what they are aimed at; 5 to systematize the experience of market leaders in submitting rationalization proposals; evaluate the effectiveness of this tool for enterprises; understand the prospects for innovation in Russia. It can be argued that our experiment was a success. The first independent rating of rationalization proposals in the history of Russia took place. We plan to make it annual and look forward to your suggestions for its improvement.

6 I Rating methodology When preparing the rating, we planned that its results would be evaluated based on the effectiveness of rationalization proposals and the value of financial indicators achieved through their implementation. As the main criterion, on the basis of which the proposals were supposed to be ranked, the economic effect was conceived: both relative (percentage of cost reduction of the enterprise) and absolute (in thousands of rubles). This decision was explained by the desire to give enterprises of various sizes and specifics the opportunity to participate in the rating on an equal footing. Nevertheless, having considered the rationalization proposals submitted by the participating enterprises, we were forced to correct the methodology for their evaluation. At first glance, financial indicators are a universal measure of effectiveness, but after analyzing the questionnaires and discovering how different and dissimilar they are, we came to the conclusion that it makes no sense to compare them directly with each other. As evidenced by the data obtained, the concept of rationalization today includes a wide variety of proposals put forward at Russian enterprises: replacement of old equipment with new; use of new raw materials and materials; change in product design; standardization and regulation; optimization without financial result; 6 process optimization; use of secondary raw materials; mechanization of manual labor; exclusion of unnecessary operations, etc. For a more objective assessment, we decided to group them as follows within the first rating of the hundred best rationalization proposals: Group 1 rationalization proposals that have a pronounced economic effect and are aimed at optimizing processes and operations. They arrived with the correct design (filling in all the items of the questionnaire, a detailed description of the essence of the rationalization and a schematic (photo) image). This group included proposals that our experts identified as optimization aimed at optimizing various kinds, including, for example, optimizing the use of resources. That is, the first group is proposals, from our point of view, the closest to the world concept of "kaizen" (rationalization proposal). Naturally, when the rationalization proposal was described in detail and qualitatively in the questionnaire, the essence of optimization and its quantitative and qualitative results were explained, it was easier to evaluate it. Group 2 rationalization proposals that have a pronounced economic effect and are aimed at modernization and reengineering. The second group includes proposals that are characterized as modernization or technological (engineering) ones that are aimed at changing the elements of the working system.

7 system and process, for example, the use of new raw materials, the use of new equipment. It is not worth it now to enter into polemics and find out what is a real kaizen proposal and whether real rationalization is inherently reengineering, since there are a great many opinions on this matter. We believe that in conditions of depreciation of fixed assets and inefficiently organized work systems, with a high potential for modernization, any proposal that allows enterprises to improve their processes or increase financial performance deserves to be called rationalization. Thus, 36 rationalization proposals were included in the first group. Basically, they were ranked according to the parameter of economic effect, however, tracking quantitative indicators, we could not help but pay attention to quality indicators. Therefore, particularly elegant and interesting solutions were also noted. The second group included 64 rationalization proposals, and in their evaluation the main criterion was the economic effect. When dividing into groups, such factors as the speed of implementation of proposals, positions held by their authors, non-financial effects, originality of the proposal, etc. were taken into account. 7

8 II Results of the rating “100 best rationalization proposals in industry 2012” Despite the short period for submitting questionnaires (2 months) and the decision to conduct the rating at the beginning of August, Russian industrial enterprises responded to our idea. More than 70 enterprises of various industries from various regions of Russia expressed their desire to take part in the rating of "100 best rationalization proposals in industry 2012". Unfortunately, due to the fact that such a competition is held for the first time, many enterprises failed to comply with all the requirements for the design and filling of questionnaires, and we were forced to exclude their candidacies. As a result, 17 enterprises were allowed to participate in the rating Structure and evaluation of the rating participants The finalists of the competition (17 enterprises) in total submitted more than 150 rationalization proposals for participation in the rating. It was extremely difficult for us to choose the top 100 among them, and we hope for the understanding of the participants. Applicants for the final were selected in such a way as to demonstrate the diversity of rationalization proposals of Russian industrial enterprises. As part of the "Production Systems 2013" rating, we plan to evaluate and compare the systems for submitting and implementing rationalization proposals, and we hope that the finalists of the rating "100 best rationalization proposals in industry 2012" will take part in it. But, despite this, we believe it is right to assess what kind of enterprises participated in the rating, how and what rationalization proposals they submitted, and what results this led to. The sectoral structure of the participating enterprises was quite expected, although the absence of representatives of the Russian energy industry among them, who are traditionally strong in the field of rationalization and implementation of optimization solutions, was somewhat surprising. It should be noted that the vast majority of rating participants (90%) are large manufacturing enterprises with a staff of 700 to 1000 people and revenues of 700 million to 110 billion rubles. 8 Fig. 1. Structure of participants by industry

9 As we can see in Fig. 1, mechanical engineering and metallurgy are in the lead, which indicates both a strong tradition of innovation that has not been lost over the past 20 years, and the presence of great potential for optimization in these industries. The reason for the latter largely lies in outdated technologies and fixed assets. Geographically, 12 regions of the Russian Federation were represented among the rating participants, which, in principle, demonstrates the sufficient prevalence of the movement of innovators. Table 1. Number of participants by region. Region Number of participants St. Petersburg, Leningrad Region 3 Republic of Tatarstan 2 Yaroslavl Region 2 Vologda Region 1 Republic of Buryatia 1 Republic of Bashkortostan 1 Nizhny Novgorod Region 1 Vladimir Region 1 Krasnodar Territory 1 Irkutsk Region 1 9 Sverdlovsk Region 1 Murmansk Region 1 Leningrad Region together is the leading region with the City of Petra. They are followed by the Republic of Tatarstan, where the development of Production systems is traditionally strong, and the Yaroslavl region. Unfortunately, a number of enterprises from various regions could not take part in the rating due to the employment of senior managers or their absence due to holidays. Otherwise, the picture of the regional prevalence of rationalization would probably be more complete. Separately, it should be noted that the development of innovation systems of participating enterprises takes place within the framework of the introduction of various concepts of production management (although we do not exclude that there is a common confusion with terminology for domestic practice). Most of the participating enterprises (more than 50%) are actively implementing the QMS (quality management system), the concept of "Lean Production" and the Production System. The age of the system for submitting and implementing rationalization proposals is also fundamental. After all, it depends on him how involved and trained the employees are, how well the submission and implementation of proposals are worked out, and how well the economists of the enterprise are able to calculate the economic effect obtained from the implementation of the proposal. Therefore, the questionnaire included the question of how long the system of rationalization has been functioning.

10 Table 2. List of enterprises finalists of the rating "100 best rationalization proposals in industry 2012" Enterprise - participant Age of the rationalization system, years 1 Apatit-Electromashservice 14 2 Armtel 2 3 BaselCement-Pikalevo 2 4 EVRAZ Nizhny Tagil Iron and Steel Works 75 5 Irkutskkabel 7 6 NPO Nauka 10 7 NPF Packer 6 8 OMZ-Special Steels Izhora Plant 2 9 OMK Almetyevsk Pipe Plant OMK Vyksa Metallurgical Plant PO ElAZ Russian Paints 4 13 Severstal Severstal-Metiz Selenginsky Pulp and Cardboard Mill AgroHolding Kuban 5 17 UEC Saturn Gas Turbines 41 enterprises noted the continuity of the traditions of rationalization since the times of the USSR. Basically, these were large metallurgical and machine-building enterprises. More than half of the enterprises (11 participants) have been implementing rationalization proposals for no more than 10 years. And a particularly pleasant surprise was the participation in the rating of enterprises with very little experience (2 years), but despite this, they are ready to demonstrate that they have something to be proud of. There were four such participants. Now let's get to know our members better. Apatit-Electromashservice presented to our analysts a whole range of rationalization proposals, which, moreover, were perfectly executed: the financial effect was calculated both in equivalent per unit of production and in relation to total annual indicators. All proposals can be divided into two areas - improvement and optimization of operations and work processes on a screw-cutting lathe and optimization of repair activities. Rationalization proposals of employees are quick and inexpensive to implement, their effect is clear, it is easy to calculate, both the presence of the “savvy” of employees and the high culture of designing the proposals themselves can be traced, which indicates a developed system of rationalization. Armtel presented only one proposal aimed at the processes of standardization,

11 lamentation and formalization of processes, and, nevertheless, it has already been implemented and brings a positive result to the enterprise. The Armtel rationalization system is at the very beginning of its development, and we are sure that participation in the competition will allow them to develop it to the international level. BaselCement-Pikalevo, the winner of the Production Systems 2012 rating in the Prospective Production System nomination, presented several proposals, some of which do not have a large financial effect, but they fully comply with the world standard of “kaizen proposals”, both in design, as well as in essence. In addition, they submitted proposals that demonstrated a good level of financial performance and a significant reduction in costs. The main directions of rationalization: optimization of existing processes and operations and optimization of repair activities. EVRAZ The Nizhny Tagil Iron and Steel Works, a large metallurgical enterprise with rich traditions, presented a large number of rationalization proposals with very serious financial results. At the same time, for the most part, they fall under the classical type of Soviet rationalization, that is, they belong to the field of activity of engineering and technical services to change and improve the elements of the working (technological) system, namely: replacement of equipment and raw materials, modernization, changes in product designs, etc. . Therefore, out of all rationalization proposals submitted by the enterprise, we could include only two proposals aimed at optimizing resources (for example, electricity) in the first group. At the same time, it is necessary to note the colossal potential of modernization, which the enterprise quite skillfully realizes. Irkutskcable, one of the leaders in the "Production Systems 2012" rating, also provided a large number of rationalization proposals for the rating. Some of them are modernization, some are optimization, and some are aimed at saving resources. Irkutskcable occupies a leading position in terms of the number of proposals that made it to the final, especially in the first group, not to mention the fact that it was he who got the fame of the best rationalization proposal of Russia this year. A reliable system for calculating the economic effect and production costs, a rationalization system covering everyone, from directors to ordinary employees, became, according to our experts, the key to the company's victories. NPO Nauka submitted quite a lot of rationalization proposals to the rating, but, unfortunately, most of them did not meet the basic selection criterion of having a recorded financial and economic effect. Despite this, a number of proposals have all the properties of optimization and are submitted by workers "from the machine", which is one of the most valuable characteristics of the rationalization system. Many proposals are aimed at changing designs, technologies, standardization and regulation. It should also be noted that the best proposals are focused primarily on improvement and optimization at the level of operations, processes and product. NPF Packer provided three rationalization proposals, two of which meet the requirements for classical kaizen proposals, but, based on small production volumes, the financial effect obtained was small compared to the proposals of other participants. For a confident victory in the rating of "100 best rationalization proposals in industry 2012", the employees of the enterprise are recommended to draw up rationalization proposals in a more detailed and high-quality manner and develop rationalization aimed at optimizing processes and organizing flows. OMZ-Special Steels Izhora Plant, a metallurgical enterprise, like EVRAZ, has distinguished itself by a considerable number of economically effective rationalization proposals, which, nevertheless, are also of an engineering, modernization nature. Therefore, out of all the rationalization proposals in the first group, we could include only one proposal aimed at optimizing resources (rational use of 11

12 charge) and brought a serious economic effect to the enterprise. OMK Almetyevsk Pipe Plant submitted only two rationalization proposals, but one of them deservedly took second place in terms of efficiency and focus on process optimization (technological transitions). Detailed and high-quality description of the essence of the proposal, high economic effect (more than 1 million rubles), rapid implementation (in 1 month) all this testifies to the promising nature of OMK's system of rationalization proposals and its reliable traditions. OMK Vyksa Metallurgical Plant, like other metallurgists, presented several rationalization proposals, also related to the improvement of the elements of the working (technological) system, although they have an economic effect. This led to the fact that only one proposal was able to get into the first group, but OMK's rationalization proposal turned out to be the most financially effective one in the second group (58 million rubles of economic effect). Software ElAZ, which became the winner of the "Production Systems 2012" rating in the "Intelligent Production System" nomination, submitted mainly rationalization proposals with a change in technologies and designs of a purely engineering nature and, due to small production volumes (against the background of metallurgical giants), could not take a worthy high place among the finalists. But based on the success of ElAZ in the development of the Production System, we are sure that for the next competition it will present the most progressive kaizen proposals aimed at optimizing processes. Russian paints, an enterprise with good references and results in the implementation of the system of rationalization proposals, submitted three rationalization proposals of an engineering nature, and all of them have a good financial effect. But we were able to attribute only one to optimization, close to kaizen, due to the fact that it was associated with a revision of the entire product identification system at the enterprise. The proposals of the Severstal group of companies also had a more engineering character, which led to the inclusion of only one proposal in the first group, but there were several of them in the second group at once. Unfortunately, the participant did not provide the names of the plants that submitted and implemented the proposals, which caused additional difficulties. We hope that in the future the success of our colleagues in the market will encourage Severstal to prepare more carefully for such ratings. Unfortunately, Severstal-Metiz presented only two rationalization proposals, one of which on the recycling of the resource (neutralized water) could take its rightful place in the first group of proposals. The Selenginsky Pulp and Cardboard Mill, which has been developing an innovation system for only two years, has submitted a number of proposals from several (apparently pilot) production sites with classic elements of modernization and reengineering. An additional advantage was that the economic effect was calculated for each proposal, but only one proposal could fall into the first group. The rest competed with the proposals of metallurgists and machine builders. MC AgroHolding Kuban participation in the rating "100 best rationalization proposals in the industry 2012" of one of the largest agricultural holdings in the country has become a very positive sign, designed to show the way to rationalization for all agricultural enterprises and representatives of the agro-processing complex. Despite the specifics of the proposals and the difficulty of comparing them with metallurgists and machine builders, the rationalization proposals of the "Kubans" managed to take worthy places in our rating. We consider the path chosen by the employees of the management company AgroHolding Kuban to be extremely promising, especially in the conditions of Russia's dependence on food imports, and we call on all enterprises in the agro-industrial complex and the food industry to follow the Kuban. 12

13 UK UEC Saturn Gas turbines this unique enterprise of the machine-building industry provided a number of proposals aimed at changing the design and technology, and only one of them was included in the first group, where, due to the economic effect, it took its rightful place. The rest competed with metallurgical enterprises in terms of economic efficiency Winners of the rating "100 best rationalization proposals in industry 2012" were also divided into two parts as follows: Table 3. Group 1 of the best rationalization proposals of Russia according to the criteria "compliance with international standards of rationalization", "qualitative description and design", "speed and ease of implementation" and "economic effect of implementation". Proposal Enterprise 1 Change in the process of marking cable drums Irkutskkabel 2 3 Adjustment of the welding stand of the mill during technological transitions Kaizen project "Organization of work on the restoration of machine parts in the ERC OMK Almetyevsk Pipe Plant Apatit-Elektromashservis 13 4 Production of a mobile hoist for the repair of pressure regulators BaselCement- Pikalevo 5 Fixture for continuous drilling on a screw-cutting lathe Apatit-Elektromashservis 6 Fixture for pressing double-row radial spherical roller bearings 3614 according to GOST into a part Apatit-Elektromashservis 7 Longitudinal stops for machining accuracy on a screw-cutting lathe Apatit-Elektromashservis 8 Fixture for fast centering of holes on a screw-cutting lathe Apatit-Elektromashservis 9 Structural change of the protective ring of the suction pipe of the pump brand 1GRT 1250/71 in order to improve performance and increase the overhaul life of Apatit-Electro mashservice 10 Installation of oil indicators in gearboxes of bucket feeders BazelCement-Pikalevo 11 Installation of an emergency stop button for elevators BaselCement-Pikalevo

14 Proposal Enterprise Change the operation algorithm of GP-7 in emergency situations (with one faulty lifting table) Use of illiquid materials as a sublayer for power cables Modification of the design of the GTA-6/8RM KVOU in order to reduce transport dimensions and transportation costs Reuse of neutralized water for cooling drawing mills OMK Vyksa Metallurgical Plant Irkutskkabel UK UEC Saturn Gas turbines Severstal-metiz 16 Recycling of lead Irkutskkabel 17 Cleaning of metallurgical equipment (electric motors, electric cabinets, contactors, etc.) by cryogenic blasting (cleaning with dry ice granules) Severstal 18 Rational charge use. OMZ-Special Steels Izhora Plant 19 Organization of transportation of reel sets in containers Irkutskcable 20 Use of alternative packaging for transportation of cables in PVC insulation with a cross-section of conductive cores of 1.5-10 sq. m. mm Irkutskkabel Use of underutilized steam energy for drying the cordel Irkutskkabel Replace diesel fuel with an aqueous solution of Polyprom detergent Reduction of electricity consumption when switching the power supply of the automatic control systems of the PGR section and refrigerators from power voltage (380V 50Hz) instead of the G-D system (rotating converters) Irkutskcable EVRAZ Nizhny Tagil Iron and Steel Works 24 Recycling of polyethylene Irkutskcable 25 Optimization of box labels Russian paints Changing the scheme of waste line drainage from washing stations. The use of cardboard for sheathing products on reels 7 Changing the operation of manufacturing the “Plate” part APRS Selenginsky Pulp and Cardboard Plant Irkutskkabel Production Association ElAZ 29 Device for testing electrical equipment Agroholding Kuban 30 Hydrotesting of KCM. PACKER 31 Use of a gas-air burner to ignite the gas at the top when shutting down blast furnaces at PPR. EVRAZ Nizhny Tagil Iron and Steel Works

15 Proposal Enterprise Improving the design of the air distributor in adsorbers Measuring system of water level in the "warm tank" reservoir The design of the refrigerator cover and the method of its implementation during repair. Changing the method of marking the inscriptions on the "Hull" part according to clause 10 of the TT of the drawing Introduction of technological improvements in the "Clamp" part NPO SCIENCE NPO SCIENCE NPO SCIENCE NPO SCIENCE NPO SCIENCE technologies”, “reengineering” and “economic effect of implementation”. Offer Enterprise 37 Casting of wheel steel into semi-blank molds, combined with the head, the inner diameter of which is 507 mm., the height of the molds is 2870 mm. OMK Vyksa Metallurgical Plant 38 Matrix for the manufacture of TPG with a cross section of 240 square meters. mm with an angle of 120 degrees Irkutsk cable Use of high-carbon ferrochrome instead of medium-carbon in the smelting of chromium-containing steel grades in the EVRAZ converter shop Nizhny Tagil Iron and Steel Works 40 Obtaining an additional amount of blast-furnace additive 41 Increasing the production of krypton-xenon concentrate 42 Reducing the cost of fuel oil facilities EVRAZ EVRAZ Nizhny Tagil Iron and Steel Works Nizhny Tagil Iron and Steel Works EVRAZ Nizhny Tagil Iron and Steel Works 43 Shortening the production time for cable products Irkutskkabel 44 Change the design of the workpiece pusher OMK Vyksa Steel Works 45 Use of lime dust from gas cleaning and aspiration systems of the lime-dolomite shop in the charge of AGC-3 Severstal 46 Processing waste from the naphthalene distillation department EVRAZ Nizhny Tagil Iron and Steel Works plant 47 Change in the design of the fuel supply for the D049 engine from the GTES-2.5 UK UEC Saturn Gas turbines

16 Offer Enterprise Elimination of joint gaps between wide and narrow walls of CCM-4 mold without mechanical impact. Increasing the actual durability of narrow slabs of MNLZ-4 molds Changing the design of the annealing furnace of the galvanizing galvanizing unit Changing the program of operation of the hydromechanical expander in the production of two-seam pipe Reducing the consumption coefficient per strip for the production of thrust brackets the production of containerboard in the cooking and washing shop. EVRAZ Nizhniy Tagil Iron and Steel Works Severstal-Metiz OMK Vyksa Steel Works EVRAZ Nizhniy Tagil Iron and Steel Works Irkutskcable Selenga Pulp and Cardboard Works 54 Reducing the cost of XLPE cables Irkutskcable 55 Putting into operation a sintering charge of waste woodworking wood chips Severstal 56 Restoring the working capacity of the Sictra AL5 drawing knife Drawing machine Irkut AL5 with critical wear in cutting coiled steel at APR-2 (manufactured in Korea) OMK Almetyevsk Pipe Plant Technology for loading iron ore materials into blast furnaces. Severstal 59 Reducing the level of rejects in the production of thrust brackets from 0.5% to 0.3% EVRAZ Nizhny Tagil Metallurgical Plant 60 Reducing steam consumption for hot water supply and heating systems of the administrative and industrial complex of the section for stripping cars of the hammer shop. Severstal 61 Replacement of filling material in the design of Irkutskkabel cables Application of an additional heat exchanger in the scheme of the condensate line of separators for continuous blowdown of medium-pressure boilers Replacement of the separating layer material in cables of the KVVGE, AKVVGE grades Use of MKRL tape instead of a refractory cord when casting ingots weighing up to 120 tons. Installing a VFD on the feed (network) pumps of steam boilers Application of digital processing of signals coming from the turbogenerator TK6-2RUKHLZ in the ACS GTA-6RM BazelCement-Pikalyovo Irkutskcable OMZ-Special Steels Izhora Plant Russian Paints UK UEC Saturn Gas turbines

17 Proposal Enterprise 67 Replacing the material for the separating layer Irkutskcable 68 Changing the design of the “Sections” of the BC and BC, which are part of the “Cyclone Blocks” for ground-based products UK UEC Saturn Gas turbines 69 Installation of a liquid meter to account for dilutions of the verstat Agroholding Kuban Division Sugar Reduction of time changeovers and the amount of waste when switching from section to section when twisting copper round TPG on Cortinovis 371 Increase in the yield of marketable products of solvent, BS-1 and inden-coumarone resin Change in the design of hot air distribution to the KVOU of GTA-6/8RM units Optimization of grain shipment from the elevator LV 3*175 of the production site 1 Modernization of the electric drive of the sulfate feeder of the soda recovery boiler 3. EVRAZ Irkutsk cable Nizhny Tagil Metallurgical Plant UK UEC Saturn Gas turbines Agroholding Kuban Ust-Labinsky KHP Selenginsky Pulp and Cardboard Plant 75 Increasing the output of marketable products of pitch distillate 76 For exchange of diesel locomotives TGM-6 for TGM-4 EVRAZ Nizhny Tagil Iron and Steel Works EVRAZ Nizhny Tagil Iron and Steel Works One-time reduction in the cost of equipping workshop 20 due to the involvement of workshop 47 in the production of charge. processing centers C630 on the milling machine FSS400 Use of metal packages from galvanized iron of the company "Metallopttorg" for smelting semi-finished products in EAF-120. Optimization of filtration of pentaphthalic lacquers in the lacquer dispensing department of shop 1 on one line. Reducing the consumption coefficient for smelting steel grade 10GN2MFA by the ESR method from cast electrodes in a mold with a diameter of 1700 mm. The use of polypropylene tape for fastening the flexible sheathing of drums Changing the scheme of pumping white strong liquor to the workshop for the production of wood-chemical products

18 Proposal Enterprise Replacing a part of metallic manganese Mp-95 with no cheaper ferromanganese FMP 78. Changing the manufacturing process of the part “Pump frame 9T TsN” Changing the design and manufacturing technology of the part “Bottom” of TsKB R B04, which is part of the “Special Sewerage Traps” of TsKB R and TsKB R Changing the technical process of forging with subsequent cutting on the USAY 1010 saw. Mechanized way of loading alumina at the complex of treatment facilities. Change in the design of winches AR, APRS and APRS 60 / OMZ-Special Steels Izhora Plant Production Association ElAZ UK UEC Saturn Gas turbines OMZ-Special Steels Izhora Plant Selenginsky Pulp and Cardboard Plant Production Association ElAZ 91 reduced profit margin. OMZ-Special Steels Izhora Plant Fastening of bronze bushings in the working cylinders of the press 1250 tf. Changing the design of the piping of the oil-sulphurizing system B of the GPA-6 RM block-container unit V OMZ-Special Steels Izhora Plant UEC Management Company Saturn Gas turbines Use of business waste of the stop housing UPR 80 / ElAZ 96 Production Association Changing the design of the air duct section and installing reinforced slide gate valves for air flows Korenovskiy elevator 97 Optimization of the process of grain loading of floor storage warehouses at the production site 2 Agroholding Kuban Ust-Labinsky KHP 98 Changing the design of the travel gear drive and oil pump at the KSHP Agroholding Kuban Korenovskiy elevator 99 Production of a rolling and rolling device for the MTZ-80,82,82.1 tractor Agroholding Kuban 100 Replacement of the filter element in the oil system of the turbo expander unit DT 5/220. OMZ-Special Steels Izhora Plant It is not easy to choose a single winner among so many proposals. And after carefully analyzing each, our experts awarded the first place to Dobretsky S.I., OAO Irkutskkabel, who presented a completely new look at the process of marking drums with cable products. The implementation of this proposal made it possible to reduce the cost of marking drums, improve its appearance and eliminate unattractive applications.