Tour tower construction mobile - collapsible design with the base block on wheels. Used for building construction installation work inside and outside the premises and in the country.

Tour tower

base unit

Ordinary section

Kinds

Structures are divided by height, platform size and the presence of a wheelbase (base unit). The material of manufacture can be steel or aluminum.

Construction tour - site dimensions

0.7x1.6 m - consists of a maximum of 5 sections up to 7.5 meters. Convenient for installation work in narrow places. The number of people on the tower should be no more than one. Equipped with 1 deck.

1x2 m - can have up to 2 decks. The maximum height is up to 8.7 meters. For an inexpensive price, there are "Economy" variations without a wheelbase. Suitable for plastering and painting works of buildings inside and outside.

1.2x2 m - the number of stair sections can reach up to 13 pieces. Reaches up to 17.1 meters. Up to 2 people can work on this tower. Quantity of scaffolds delivered in a complete set - 2 pieces.

1.6x1.6 m - a more stable model with a square platform. It is assembled up to 14 sections, with a maximum height of 18.3 meters. The kit comes with 2 scaffolds. It is applied to finishing of facades of buildings.

1.6x2.0 m - a professional type of tower tours up to 20.7 meters. Must be completed with a wheel block with at least 2 decks. A large platform allows up to 2 people to work at the same time. It is used for finishing of a facade and installation works.

For repair and construction works, a universal tour tower is effectively used, which ensures the safe work of specialists at a height of 1 to 25 m. Due to its design and manufacturing materials, it is able to withstand a load of up to 250 kg per 1 sq. m. m area. According to its design, it is a collapsible structure made of metal or aluminum. Facing and insulation of facades, roofing and finishing works - this is a far from complete range of applications for a combined tour tower. Thanks to its mobility and installed wheels, it can move along the construction site, thereby ensuring the continuity of the work being done. The tower on wheels is effectively used in all types of repair and construction work.

Types and types of building towers

According to its quality characteristics and design, the construction tour is divided into:

- economy - option;

- standard towers;

- reinforced product;

- towers are eurostandard.

The main differences are both in the height of the product and in the size of the working platform. In addition, different versions of towers have different installation heights and section spacings.

The presented products comply with the norms and standards of GOST, are certified products, and have high quality characteristics. Each construction tour tower has a passport and a certificate. The production of the product is carried out on a modern technological equipment, using innovative solutions. The materials used with the applied powder coating allow the towers to be used for a long period of time.

Convenience when using mobile towers

The design of the towers allows them to be quickly assembled and dismantled, and moved not only along the facade of the building, but also transported to other work sites. In addition, the collapsible design has clear advantages over other paving materials, and can be installed at any desired height, up to 25 meters.

The construction tower of the tour, which you can buy on our web resource, has all the positive characteristics, excellent quality and high strength. Delivery in Moscow and the Russian Federation is carried out in the shortest possible time. So, in Moscow, at the construction site, it can be delivered in three hours.

A lift is a lifting machine of discontinuous (cyclic) or continuous action for lifting cargo and people in special load-carrying devices moving along rigid vertical (sometimes inclined) guides or rail tracks. According to the method of transferring the impact from the drive to the load-carrying devices, cable, chain, rack, screw and plunger lifts are distinguished. Rope hoists, in which load-carrying devices are suspended on steel ropes, enveloping traction sheaves or wound on drums of hoisting winches, have become predominantly widespread. In lifts with traction sheaves that transmit traction due to friction forces, load-carrying devices (cabin, cage, skip, platform, trolley or wagon) are balanced by other similar devices or a counterweight (in passenger elevators - only by a counterweight), also moving along guides. In drum lifts, balancing reduces the load on the drive.

Lifts are usually electrical or less often hydraulically driven.

Mast lift - a lifting machine designed to lift goods or people to a height, supply building materials, carrying out finishing or installation work along the facade of buildings. According to the principle of operation, it belongs to the class of machines of cyclic action. Also called a post lift.

The main element of the mast hoist is a metal rigid truss mast of triangular or rectangular section, which serves as a guide when the cargo platform moves along it. The mast can be either self-supporting or fixed to the building wall using special brackets and telescopic rods.

The lift mast is assembled at the installation stage from several sections, which are fastened with bolts. As the height of the building increases, the lift mast is increased with the help of intermediate sections.

Rope pulley systems are used as a lifting mechanism in mast lifts.

Mounting towers- This is a special design that is used in the production of construction and installation, finishing, repair work, when laying the walls of residential buildings, installing blocks, ceilings, maintaining lighting networks, alarm systems, communication systems, air conditioning and ventilation systems and carrying out other work that requires the safe work of people at height, without the use of additional safety equipment.

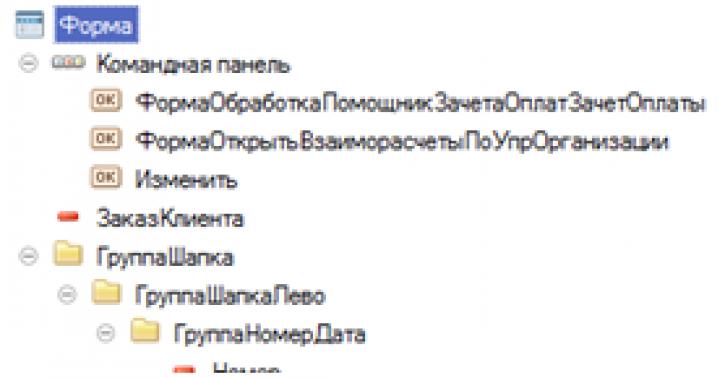

Mounting towers - are a mobile metal structure in the form of a tower, made up of ladders and platforms. The towers are equipped with wheels for easy movement of the structure along construction site. Main technical specifications tour towers are: full height, working height, maximum load on the deck, dimensions of the working platform, section step, number of decks.

The construction assembly tower consists of a base block in which section frames are installed, which are interconnected by dumbbells and fastening ties. Then the fencing frames and decking are installed. One of the floorings, for convenience, is equipped with a special hatch. In order for the mounting towers to be more reliable and stable, a stabilizer is installed at their base, which increases the stability of the tower and the safety of people when working at high altitudes.

Metal towers can be found on almost every construction site. Unlike scaffolding, erection towers have a lighter design, simplicity and ease of assembly and transportation. Can be used for both indoor and outdoor work.

Construction erection towers consist of several levels, are easily adjustable in height and have a modular unified design, which makes it easy, if necessary, to build them up with additional sections to increase the working height, or to connect them to other platforms and other structures of construction equipment. Towers round are convenient in operation and transportation and are effective in use. Do not require special maintenance and adjustment.

Distinctive features of the mounting tower are not only compactness and low weight, but also corrosion resistance. That guarantees a long service life of this type of construction equipment.

Mounting mobile telescopic tower (mast lift)

The telescopic lift is a worthy replacement for scissor lifts and is available in self-propelled and stationary versions. This type of lift is equipped with a reliable retractable mast, and the entire contraction is highly reliable and has impressive performance characteristics. In addition, all models meet the standards international standards security.

The load capacity of this type of lift is lower than, for example, scissor towers, but there are a number of very significant advantages. For example, a small weight of equipment, which is provided by a light aluminum mast, and compact dimensions make it possible not only to use these lifts in rooms with limited space, but also to transport them to the right place without much difficulty. In addition, the contraction of the mast allows for smooth movement of loads, with virtually no oscillation.

Self-propelled lifts Malta reliably protected from tipping, thanks to the distribution of weight - the center of gravity is shifted towards the drive. Non-self-propelled towers are equipped with special articulated supports, which guarantee a secure fixation during operation and ensure an even level during installation. In addition, non-self-propelled towers can be equipped with self-propelled carts that help move the lift within the premises. By the way, you can move the tower in the raised position.

The PTS company offers its customers equipment of well-known world trademarks, which differs high quality and reliability. Equipment manufactured by the company Malta, has long established itself in domestic market. Owner reviews are the most eloquent confirmation of this. It is worth remembering that it is very important to choose a lift so that it meets the requirements of technological processes.

The purpose of the telescopic tower:

the telescopic tower is designed for vertical movement of small loads and workers in order to carry out works of a different nature, for example, repair and construction or installation. Lifting height - up to ten meters;

The mobile mast lift Malte is indispensable in the process of working on large areas with high ceilings, as it ensures the delivery of everything necessary to the place of work, eliminating the need for bulky scaffolding and other equipment;

The design of the tower allows it to be used at temperatures from -10 to +38 degrees Celsius.

Design features:

- The aluminum mast ensures the lightness of the whole structure;

- Compact dimensions allow the use of towers in narrow spaces and easily transport them;

- Seamless transmission provides a smooth ride during the descent and ascent;

- The towers of the LM WPAM series are equipped with hinged supports that prevent tipping over. Special sensors do not allow the platform to be raised if the support is not installed;

- Towers LM WP have a center of gravity shifted to the bottom, which also ensures the stability of the structure;

- In order to increase the level of safety, all buttons, including the emergency stop button, as well as the platform lowering valve, are duplicated;

- Platforms of the LM WPAM series are made in modifications that allow them to be powered both from the mains with alternating current and with direct current.

Mobile tower t its control principle:

| Mobile tower LM WPAM-1 series. | |

|

Tower single non-self-propelled telescopic with a single aluminum mast. Working Heights: 8, 10 and 12 meters. Load capacity: 125-150 kg. Drive unit Technical data of models: |

|

| LM WPAM-2 series. | |

|

Non-self-propelled telescopic tower with a double aluminum mast. Working Heights: 8, 10, 12 and 14 meters. Load capacity: 200-300 kg. Drive unit are supplied in two versions: AC - from household AC 220 V; Technical data of models: . |

|

Control principle:

- This series is equipped with a self-propelled electric trolley;

- Lifting and lowering and movement of the mast lift is carried out using the control panel located in the cradle;

- Movement can be carried out with the lift cradle raised;

- Emergency stop and descent buttons are located in the cradle and on the trolley of the mast lift;

- Maneuvering of the lift is carried out by multi-speed or multi-directional movement of the driving wheels.

| LM WPAP-1 series. | |

|

Tower single self-propelled telescopic with a single aluminum mast. Working Heights: 8 and 9.5 meters. Load capacity: 125-150 kg. Drive unit: DC - from batteries, direct current 12 V. Technical data of models: . |

|

| LM WPAP-2 series. | |

|

Self-propelled telescopic tower with a double aluminum mast. Working Heights: 9.5 and 11 meters. Load capacity: 150-200 kg. Drive unit: DC - from batteries, direct current 12 V. Technical data of models: . |

|

|

Description: Mobile small-sized towers with electric lifting drive (alternating current 220 V and battery 12 V). Small-sized tower lifts are an easy and convenient means of lifting in the exhibition hall, warehouse, shop, airport, etc. Small dimensions make it easy to maneuver in narrow spaces, can be placed in an elevator, passed through an ordinary door. Design feature of the tower: has two convenient transport positions, one of them provides easy, manually, loading into a car with a low side such as a Gazelle or a pickup truck. For this function, a removable battery pack is provided in the model equipped with a battery. |

|

|

|

Control principle:

- The trolley with the platform is equipped with two sets of parallel control panels, the upper one - directly on the lifting cradle, and the lower one - on the trolley frame;

- The platform is raised / lowered by holding the button ("up" "UP") or "down" ("DOWN")) in the pressed position. When the button is released, the platform stops;

- Each console also has an emergency stop button for the platform operation.

Material lifts are a technique for lifting people, light loads or tools vertically upwards. Most often, this technique is used to implement:

- mounting;

- finishing;

- repair;

- facade works;

- collection of goods from high shelves.

Lifts are quite compact and mobile type of equipment, so they can be used for both external and internal work.

Varieties

Warehouse facade lifting towers differ in several ways: by the type of construction and movement.

By type of construction, lifts are:

- mast - the cabin is fixed on one or two masts. Such lifts can be single and double. Can lift people and cargo weighing up to 300 kg;

- scissor - represent a support base with a scissor mechanism for lifting the cab. Unlike telescopic (mast) they have a larger cabin and can lift people and cargo weighing up to 1 ton.