Nuclear power plant(NPP) - a complex of technical structures designed to generate electrical energy by using the energy released in a controlled nuclear reaction.

Uranium is used as a common fuel for nuclear power plants. The fission reaction is carried out in the main unit of a nuclear power plant - a nuclear reactor.

The reactor is mounted in a steel case designed for high pressure - up to 1.6 x 107 Pa, or 160 atmospheres.

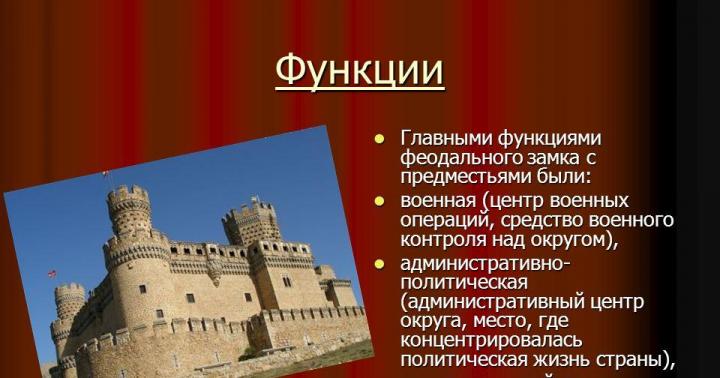

The main parts of VVER-1000 are:

1. The core, where nuclear fuel is located, a chain reaction of nuclear fission proceeds and energy is released.

2. Neutron reflector surrounding the core.

3. Coolant.

4. Protection control system (CPS).

5. Radiation protection.

Heat in the reactor is released due to the chain reaction of fission of nuclear fuel under the action of thermal neutrons. In this case, nuclear fission products are formed, among which there are both solids and gases - xenon, krypton. Fission products have a very high radioactivity, so the fuel (uranium dioxide tablets) is placed in sealed zirconium tubes - TVELs (fuel elements). These tubes are combined several pieces side by side into a single fuel assembly. To control and protect a nuclear reactor, control rods are used that can be moved along the entire height of the core. The rods are made from substances that strongly absorb neutrons, such as boron or cadmium. With the deep introduction of the rods, the chain reaction becomes impossible, since the neutrons are strongly absorbed and removed from the reaction zone. The rods are moved remotely from the control panel. With a small movement of the rods, the chain process will either develop or decay. In this way, the power of the reactor is regulated.

The scheme of the station is two-circuit. The first, radioactive, circuit consists of one VVER 1000 reactor and four circulation cooling loops. The second circuit, non-radioactive, includes steam generator and water supply units and one turbine unit with a capacity of 1030 MW. The primary coolant is high-purity non-boiling water at a pressure of 16 MPa with the addition of a solution of boric acid, a strong neutron absorber, which is used to control the power of the reactor.

1. The main circulation pumps pump water through the reactor core, where it is heated to a temperature of 320 degrees due to the heat released during a nuclear reaction.

2. The heated coolant gives off its heat to the water of the secondary circuit (working fluid), evaporating it in the steam generator.

3. The cooled coolant enters the reactor again.

4. The steam generator produces saturated steam at a pressure of 6.4 MPa, which is fed to the steam turbine.

5. The turbine drives the rotor of the electric generator.

6. The exhaust steam is condensed in the condenser and fed back to the steam generator by the condensate pump. To maintain a constant pressure in the circuit, a steam volume compensator is installed.

7. The heat of steam condensation is removed from the condenser by circulating water, which is supplied by a feed pump from the cooling pond.

8. Both the first and second circuits of the reactor are sealed. This ensures the safety of the reactor for personnel and the public.

If it is impossible to use a large amount of water for steam condensation, instead of using a reservoir, the water can be cooled in special cooling towers (cooling towers).

The safety and environmental friendliness of the reactor operation are ensured by strict compliance with the regulations (operational rules) and a large number of control equipment. All of it is designed for thoughtful and effective management reactor.

Emergency protection of a nuclear reactor - a set of devices designed to quickly stop a nuclear chain reaction in the reactor core.

Active emergency protection is automatically triggered when one of the parameters of a nuclear reactor reaches a value that can lead to an accident. Such parameters can be: temperature, pressure and flow rate of the coolant, level and rate of power increase.

The executive elements of emergency protection are, in most cases, rods with a substance that absorbs neutrons well (boron or cadmium). Sometimes a liquid scavenger is injected into the coolant loop to shut down the reactor.

In addition to active protection, many modern designs also include elements of passive protection. For example, modern versions of VVER reactors include the "Emergency Core Cooling System" (ECCS) - special tanks with boric acid located above the reactor. In the event of a maximum design basis accident (rupture of the primary cooling circuit of the reactor), the contents of these tanks are by gravity inside the reactor core and the nuclear chain reaction is quenched by a large amount of a boron-containing substance that absorbs neutrons well.

According to the "Nuclear Safety Rules for Reactor Installations nuclear power plants", at least one of the provided reactor shutdown systems must perform the function of emergency protection (EP). Emergency protection must have at least two independent groups of working elements. At the signal of the EP, the working elements of the EP must be activated from any working or intermediate positions.

The AZ equipment must consist of at least two independent sets.

Each set of AZ equipment must be designed in such a way that, in the range of neutron flux density changes from 7% to 120% of the nominal value, protection is provided for:

1. According to the density of the neutron flux - at least three independent channels;

2. According to the rate of neutron flux density increase - by at least three independent channels.

Each set of AZ equipment must be designed in such a way that, in the entire range of process parameter changes established in the reactor plant (RP) design, emergency protection is provided by at least three independent channels for each process parameter for which protection is necessary.

The control commands of each set for AZ actuators must be transmitted over at least two channels. When one channel is taken out of operation in one of the AZ equipment sets without this set being taken out of operation, an alarm signal should be automatically generated for this channel.

Tripping of emergency protection should occur at least in the following cases:

1. Upon reaching the AZ setpoint in terms of neutron flux density.

2. Upon reaching the AZ setpoint in terms of the rate of increase in the neutron flux density.

3. In the event of a power failure in any set of AZ equipment and CPS power supply buses that have not been taken out of operation.

4. In case of failure of any two of the three protection channels in terms of the neutron flux density or in terms of the rate of neutron flux increase in any set of AZ equipment that has not been decommissioned.

5. When the AZ settings are reached technological parameters that need to be protected.

6. When initiating the operation of the AZ from the key from the block control point (BCR) or the backup control point (RCP).

The material was prepared by the online editors www.rian.ru based on information from RIA Novosti and open sources

NUCLEAR POWER PLANT(NPP), a power plant that uses the heat released in a nuclear reactor as a result of a controlled chain reaction of nuclear fission of heavy elements to generate electricity (in the main. $\ce(^(233)U, ^(235)U, ^(239)Pu)$). The heat generated in core nuclear reactor, is transmitted (directly or through an intermediate coolant) working fluid (predominantly water vapor), which drives steam turbines with turbogenerators.

A nuclear power plant is, in principle, an analogue of a conventional thermal power plant(TPP), in which a nuclear reactor is used instead of a steam boiler furnace. However, despite the similarity of the fundamental thermodynamic schemes of nuclear and thermal power plants, there are also significant differences between them. The main ones are the environmental and economic advantages of nuclear power plants over thermal power plants: nuclear power plants do not need oxygen to burn fuel; they practically do not pollute the environment with sulfurous and other gases; nuclear fuel has a significantly higher calorific value (fission of 1 g of U or Pu isotopes releases 22,500 kWh, which is equivalent to the energy contained in 3,000 kg hard coal), which dramatically reduces its volume and the cost of transportation and handling; world energetic resources of nuclear fuel significantly exceed the natural reserves of hydrocarbon fuel. In addition, the use of nuclear reactors (of any type) as an energy source requires a change in the thermal schemes adopted at conventional thermal power plants and the introduction of new elements into the structure of nuclear power plants, for example. biological protection (see Radiation safety), spent fuel refueling systems, fuel pools, etc. Transfer of thermal energy from a nuclear reactor to steam turbines carried out by means of a coolant circulating through sealed pipelines, in combination with circulation pumps, forming the so-called. reactor circuit or loop. Normal and heavy water, water vapor, liquid metals, organic liquids, and some gases (for example, helium, carbon dioxide) are used as heat carriers. The circuits through which the coolant circulates are always closed to avoid leakage of radioactivity, their number is determined mainly by the type of nuclear reactor, as well as the properties of the working fluid and coolant.

At nuclear power plants with a single-loop scheme (Fig., a) the coolant is also a working fluid, the entire circuit is radioactive and therefore surrounded by biological protection. When using an inert gas as a coolant, such as helium, which is not activated in the neutron field of the core, biological protection is necessary only around the nuclear reactor, since the coolant is not radioactive. The coolant - the working fluid, heating up in the reactor core, then enters the turbine, where its thermal energy is converted into mechanical energy and then in the electric generator - into electrical energy. The most common are single-circuit nuclear power plants with nuclear reactors, in which the coolant and neutron moderator serves as water. The working fluid is formed directly in the core when the coolant is heated to boiling. Such reactors are called boiling water reactors, in the world nuclear power industry they are referred to as BWR (Boiling Water Reactor). In Russia, boiling water reactors with a water coolant and a graphite moderator - RBMK (high power channel reactor) have become widespread. The use of high-temperature gas-cooled reactors (with helium coolant) - HTGR (HTGR) at NPPs is considered promising. The efficiency of single-loop NPPs operating in a closed gas turbine cycle can exceed 45–50%.

With a two-circuit scheme (Fig., b) the primary coolant heated in the core is transferred to the steam generator ( heat exchanger) thermal energy to the working fluid in the second circuit, after which it is returned to the core by the circulation pump. The primary coolant can be water, liquid metal or gas, and the working fluid is water, which turns into water vapor in the steam generator. The primary circuit is radioactive and is surrounded by biological shielding (except when an inert gas is used as a coolant). The second circuit is usually radiation safe, since the working fluid and the coolant of the primary circuit do not come into contact. The most widespread are double-loop nuclear power plants with reactors in which water is the primary coolant and moderator, and steam is the working fluid. This type of reactor is referred to as VVER - pressurized water power. reactor (PWR - Power Water Reactor). The efficiency of nuclear power plants with VVER reaches 40%. In terms of thermodynamic efficiency, such NPPs are inferior to single-loop NPPs with HTGR if the temperature of the gas coolant at the exit from the core exceeds 700 °C.

Three-circuit thermal schemes (Fig., in) are used only in those cases when it is necessary to completely exclude the contact of the coolant of the first (radioactive) circuit with the working fluid; for example, when the core is cooled with liquid sodium, its contact with the working fluid (steam) can lead to a major accident. Liquid sodium as a coolant is used only in fast neutron nuclear reactors (FBR - Fast Breeder Reactor). A feature of nuclear power plants with a fast neutron reactor is that, simultaneously with the generation of electrical and thermal energy, they reproduce fissile isotopes suitable for use in thermal nuclear reactors (see Fig. Breeder Reactor).

Nuclear power plant turbines usually operate on saturated or slightly superheated steam. When using turbines operating on superheated steam, saturated steam is passed through the reactor core (through special channels) or through a special heat exchanger - a hydrocarbon-fueled superheater to increase the temperature and pressure. The thermodynamic efficiency of the NPP cycle is the higher, the higher the parameters of the coolant, the working fluid, which are determined by the technological capabilities and properties of structural materials used in the NPP cooling circuits.

At nuclear power plants, much attention is paid to the purification of the coolant, since the natural impurities present in it, as well as corrosion products that accumulate during the operation of equipment and pipelines, are sources of radioactivity. The degree of purity of the coolant largely determines the level of the radiation situation in the premises of the NPP.

Nuclear power plants are almost always built near energy consumers, because the cost of transporting nuclear fuel to nuclear power plants, in contrast to hydrocarbon fuel for thermal power plants, has little effect on the cost of generated energy (usually, nuclear fuel in power reactors is replaced with a new one once every several years). years), and the transmission of both electrical and thermal energy over long distances significantly increases their cost. Nuclear power plants are built on the leeward side of the nearest settlement, a sanitary protection zone and an observation zone are created around it, where the population is unacceptable. Control and measuring equipment for continuous monitoring of the environment is placed in the observation zone.

NPP - the basis nuclear power. Their main purpose is the production of electricity (nuclear power plants of the condensing type) or the combined production of electricity and heat (nuclear combined heat and power plants - ATES). At the NPP, part of the steam exhausted in the turbines is diverted to the so-called. network heat exchangers for heating water circulating in closed heat supply networks. In some cases, the thermal energy of nuclear reactors can only be used for heating needs (nuclear heat supply stations - AST). In this case, the heated water from the heat exchangers of the first and second circuits enters the network heat exchanger, where it gives off heat to the network water and then returns to the circuit.

One of the advantages of nuclear power plants compared to conventional thermal power plants is their high environmental friendliness, which is maintained with qualification. operation of nuclear reactors. The existing NPP radiation safety barriers (fuel rod cladding, nuclear reactor vessel, etc.) prevent contamination of the coolant with radioactive fission products. A protective shell (containment) is being erected over the reactor hall of the NPP to prevent radioactive materials from entering the environment during the most severe accident - depressurization of the primary circuit, melting of the core. NPP personnel training provides for training on special simulators (NPP simulators) for practicing actions both in normal and emergency situations. The NPP has a number of services that ensure the normal functioning of the station, the safety of its personnel (for example, dosimetric control, ensuring sanitary and hygienic requirements, etc.). On the territory of the nuclear power plant, temporary storage facilities are created for fresh and spent nuclear fuel, for liquid and solid radioactive waste that appears during its operation. All this leads to the fact that the cost of an installed kilowatt of power at nuclear power plants is more than 30% higher than the cost of a kilowatt at thermal power plants. However, the cost of energy supplied to the consumer, generated at nuclear power plants, is lower than at thermal power plants, due to the very small share of the fuel component in this cost. Due to high efficiency and features of power control, NPPs are usually used in basic modes, while the installed capacity utilization factor of NPPs can exceed 80%. As the share of nuclear power plants in the total energy balance of the region increases, they can also operate in a maneuver mode (to cover load irregularities in the local energy system). The ability of nuclear power plants to operate for a long time without changing fuel allows them to be used in remote regions. NPPs have been developed whose equipment layout is based on the principles implemented in shipboard nuclear power plants. installations (see Nuclear ship). Such nuclear power plants can be placed, for example, on a barge. Promising nuclear power plants with HTGR, generating thermal energy for the implementation of technological processes in the metallurgical, chemical and oil industries, in the gasification of coal and shale, in the production of synthetic hydrocarbon fuels. The NPP operation life is 25–30 years. The decommissioning of a nuclear power plant, the dismantling of the reactor and the reclamation of its site to the state of a “green lawn” is a complex and expensive organizational and technical measure carried out according to plans developed in each specific case.

The world's first operating nuclear power plant with a capacity of 5000 kW was launched in Russia in 1954 in the city of Obninsk. In 1956, the nuclear power plant at Calder Hall in the UK (46 MW) was put into operation, in 1957 the nuclear power plant at Shippingport in the USA (60 MW) was put into operation. In 1974, the world's first thermal power plant, the Bilibinskaya (Chukotka Autonomous Okrug), was launched. Mass construction of large economical nuclear power plants began in the 2nd half. 1960s However, after the accident (1986) at the Chernobyl nuclear power plant, the attractiveness of nuclear energy has noticeably decreased, and in a number of countries that have sufficient own traditional fuel and energy resources or access to them, the construction of new nuclear power plants has actually stopped (Russia, USA, Great Britain, Germany). At the beginning of the 21st century, on March 11, 2011, in the Pacific Ocean off the east coast of Japan, as a result of a strong earthquake with a magnitude of 9.0 to 9.1 and the subsequent tsunami(wave height reached 40.5 m) at the Fukushima1 nuclear power plant (Okuma Township, Fukushima Prefecture) the largesttechnological disaster– radiation accident of the maximum level 7 according to the International Nuclear Event Scale. The tsunami hit disabled external power supplies and backup diesel generators, which caused the inoperability of all normal and emergency cooling systems and led to the melting of the reactor core at power units 1, 2 and 3 in the first days of the accident. In December 2013, the nuclear power plant was officially closed. As of the first half of 2016, a high level of radiation makes it impossible to work not only for people in reactor buildings, but also for robots, which, due to high level radiation is out of order. It is planned that the removal of soil layers to special storage facilities and its destruction will take 30 years.

31 countries of the world use nuclear power plants. Valid for 2015 is approx. 440 nuclear power reactors (power units) with a total capacity of more than 381,000 MW (381 GW). OK. 70 nuclear reactors are under construction. The world leader in terms of share in total electricity generation is France (second place in terms of installed capacity), in which nuclear power is 76.9%.

The largest nuclear power plant in the world in 2015 (in terms of installed capacity) is Kashiwazaki-Kariwa (Kashiwazaki, Niigata Prefecture, Japan). There are 5 boiling water reactors (BWRs) and 2 advanced boiling water reactors (ABWRs) in operation, with a combined capacity of 8212 MW (8.212 GW).

The largest nuclear power plant in Europe is the Zaporozhye NPP (Energodar, Zaporozhye region, Ukraine). Since 1996, 6 power units with VVER-1000 reactors have been operating with a total capacity of 6,000 MW (6 GW).

| Table 1. The largest consumers of nuclear power in the world | |||

| State | Number of power units | Total power (MW) | Total generated electricity (billion kWh/year) |

| USA | 104 | 101 456 | 863,63 |

| France | 58 | 63 130 | 439,74 |

| Japan | 48 | 42 388 | 263,83 |

| Russia | 34 | 24 643 | 177,39 |

| South Korea | 23 | 20 717 | 149,2 |

| China | 23 | 19 907 | 123,81 |

| Canada | 19 | 13 500 | 98,59 |

| Ukraine | 15 | 13 107 | 83,13 |

| Germany | 9 | 12 074 | 91,78 |

| Great Britain | 16 | 9373 | 57,92 |

The United States and Japan are developing mini-nuclear power plants with a capacity of about 10–20 MW for heat and power supply to individual industries, residential complexes, and, in the future, individual houses. Small-sized reactors are created using safe technologies that greatly reduce the possibility of leakage of nuclear material.

As of 2015, 10 NPPs operate in Russia, which operate 34 power units with a total capacity of 24,643 MW (24.643 GW), of which 18 power units are with VVER-type reactors (including 11 VVER-1000 power units and 6 VVER-440 power units of various modifications); 15 power units with channel reactors (11 power units with RBMK-1000 type reactors and 4 power units with EGP-6 type reactors - Energy Heterogeneous Loop Reactor with 6 coolant circulation loops, electric power 12 MW); 1 power unit with sodium-cooled fast neutron reactor BN-600 (in the process of commissioning commercial operation there is 1 power unit BN-800). According to the Federal Target Program "Development of the Russian Nuclear Power Industry Complex", by 2025 the share of electricity generated at nuclear power plants in the Russian Federation should increase from 17 to 25% and amount to approx. 30.5 GW. It is planned to build 26 new power units, 6 new nuclear power plants, two of which are floating (Table 2).

| Table 2. NPPs operating on the territory of the Russian Federation | ||||

| NPP name | Number of power units | Years of commissioning of power units | Total installed capacity (MW) | Reactor type |

| Balakovo NPP (near Balakovo) | 4 | 1985, 1987, 1988, 1993 | 4000 | VVER-1000 |

| Kalinin NPP [125 km from Tver on the banks of the Udomlya River (Tver region)] | 4 | 1984, 1986, 2004, 2011 | 4000 | VVER-1000 |

| Kursk NPP (near the city of Kurchatov on the left bank of the Seim River) | 4 | 1976, 1979, 1983, 1985 | 4000 | RBMK-1000 |

| Leningrad NPP (near Sosnovy Bor) | 4 under construction - 4 | 1973, 1975, 1979, 1981 | 4000 | RBMK-1000 (the first plant in the country with reactors of this type) |

| Rostov NPP (located on the banks of the Tsimlyansk reservoir, 13.5 km from the city of Volgodonsk) | 3 | 2001, 2010, 2015 | 3100 | VVER-1000 |

| Smolensk NPP (3 km from the satellite town of Desnogorsk) | 3 | 1982, 1985, 1990 | 3000 | RBMK-1000 |

| Novovoronezh NPP (near Novovoronezh) | 5; (2 - withdrawn), under construction - 2. | 1964 and 1969 (withdrawn), 1971, 1972, 1980 | 1800 | VVER-440; VVER-1000 |

| Kola NPP (200 km south of Murmansk on the shores of Lake Imandra) | 4 | 1973, 1974, 1981, 1984 | 1760 | VVER-440 |

| Beloyarsk NPP (near Zarechny) | 2 | 1980, 2015 | 600 800 | BN-600 BN-800 |

| Bilibino NPP | 4 | 1974 (2), 1975, 1976 | 48 | EGP-6 |

Projected NPPs in the Russian Federation

Since 2008, according to the new project NPP-2006 (the project of the Russian nuclear power plant of the new generation "3+" with improved technical and economic indicators), Novovoronezh NPP-2 (near Novovoronezh NPP) is being built, which provides for the use of VVER-1200 reactors. The construction of 2 power units with a total capacity of 2400 MW is underway, in the future it is planned to build 2 more.

The Baltic NPP provides for the use of a VVER-1200 reactor plant with a capacity of 1200 MW; power units - 2. The total installed capacity is 2300 MW. The commissioning of the first unit is planned for 2020. The Federal Atomic Energy Agency of Russia is conducting a project to create low-power floating nuclear power plants. The Akademik Lomonosov nuclear power plant under construction will be the world's first floating nuclear power plant. The floating station can be used to generate electricity and heat, as well as to desalinate sea water. It can produce from 40 to 240 thousand m 2 of fresh water per day. The installed electric power of each reactor is 35 MW. Commissioning of the station is planned for 2018.

International projects of Russia on nuclear energy

23.9.2013 Russia handed over to Iran the operation of the Bushehr NPP (Bushir) , near the town of Bushehr (Bushir stop); number of power units - 3 (1 built, 2 - under construction); reactor type - VVER-1000. NPP "Kudankulam", near the city of Kudankulam (Tamil Nadu, India); number of power units - 4 (1 - in operation, 3 - under construction); reactor type - VVER-1000. NPP "Akkuyu", near the city of Mersin (il Mersin, Turkey); number of power units - 4 (under construction); reactor type - VVER-1200; Belarusian NPP (Ostrovets, Grodno region, Belarus); number of power units - 2 (under construction); reactor type - VVER-1200. NPP Hanhikivi 1 (Cape Hanhikivi, Pohjois-Pohjanmaa region, Finland); number of power units - 1 (under construction); reactor type - VVER-1200.

Nuclear power plants

Nuclear power plants are nuclear installations that produce energy, while observing the specified modes under certain conditions. For these purposes, the territory defined by the project is used, where nuclear reactors are used in combination with the necessary systems, devices, equipment and structures to perform the tasks. Specialized personnel are involved to fulfill the target tasks.

All nuclear power plants in Russia

The history of nuclear energy in our country and abroad

The second half of the 1940s was marked by the beginning of work on the creation of the first project involving the use of a peaceful atom to generate electricity. In 1948, I.V. Kurchatov, guided by the task of the party and Soviet government, made a proposal to start work on the practical use of atomic energy to generate electricity.

Two years later, in 1950, not far from the village of Obninskoye, located in Kaluga region, the construction of the first nuclear power plant on the planet was launched. The launch of the world's first industrial nuclear power plant, with a capacity of 5 MW, took place on 06/27/1954. The Soviet Union became the first power in the world to succeed in using the atom for peaceful purposes. The station was opened in Obninsk, which had received the status of a city by that time.

But Soviet scientists did not stop there, they continued to work in this direction, in particular, only four years later, in 1958, the operation of the first stage of the Siberian NPP was started. Its power was many times greater than the station in Obninsk and amounted to 100 MW. But for domestic scientists, this was not the limit, upon completion of all work, the design capacity of the station was 600 MW.

In the open spaces Soviet Union, the construction of nuclear power plants, took on a massive scale at that time. In the same year, the construction of the Beloyarsk NPP was launched, the first stage of which, already in April 1964, supplied the first consumers. The geography of the construction of nuclear power plants entangled the whole country with its network, in the same year they launched the first unit of the nuclear power plant in Voronezh, its capacity was 210 MW, the second unit launched five years later in 1969, boasted a capacity of 365 MW. the boom in the construction of nuclear power plants did not subside throughout the Soviet era. New stations, or additional units already built, were launched at intervals of several years. So, already in 1973, Leningrad received its own nuclear power plant.

However, the Soviet state was not the only one in the world who was able to master such projects. In the UK, they also did not doze off and, realizing the prospects of this direction, actively studied this issue. Just two years later, after the opening of the station in Obninsk, the British launched their own project for the development of peaceful atom. In 1956, the British launched their own station in the town of Calder-Hall, the power of which exceeded the Soviet counterpart and amounted to 46 MW. Not lagging behind on the other side of the Atlantic, a year later, the Americans solemnly launched the station in Shippingport. The capacity of the facility was 60 MW.

However, the development of the peaceful atom was fraught with hidden threats, which the whole world soon learned about. The first sign was a major accident in Three Mile Island that occurred in 1979, but after it there was a disaster that hit the whole world, in the Soviet Union, in small town Chernobyl was a large-scale disaster, it happened in 1986. The consequences of the tragedy were irreparable, but besides this, this fact made the whole world think about the advisability of using nuclear energy for peaceful purposes.

World luminaries in this industry are seriously thinking about improving the safety of nuclear facilities. The result was the founding assembly, which was organized on May 15, 1989 in the Soviet capital. The Assembly decided to create a World Association, which should include all operators of nuclear power plants, its generally recognized abbreviation is WANO. In the course of implementing its programs, the organization systematically monitors the increase in the level of safety of nuclear power plants in the world. However, despite all the efforts made, even the most modern and at first glance seemingly safe objects cannot withstand the onslaught of the elements. It was because of the endogenous catastrophe, which manifested itself in the form of an earthquake and the tsunami that followed it, in 2011 there was an accident at the Fukushima-1 station.

Atomic blackout

NPP classification

Nuclear power plants are classified according to two criteria, the type of energy they produce and the type of reactors. Depending on the type of reactor, the amount of generated energy, the level of safety, and also what kind of raw materials are used at the station are determined.

According to the type of energy that stations produce, they are divided into two types:

Nuclear power plants. Their main function is to generate electrical energy.

Nuclear thermal power plants. Due to the heating plants installed there, which use the heat losses that are inevitable at the station, it becomes possible to heat the network water. Thus, these stations, in addition to electricity, generate thermal energy.

After examining many options, scientists came to the conclusion that the most rational are their three varieties, which are currently used throughout the world. They differ in a number of ways:

- Fuel used;

- Applied coolants;

- Cores operated to maintain the required temperature;

- A type of moderator that determines the reduction in the speed of neutrons that are released during decay and are so necessary to support a chain reaction.

The most common type is the reactor, which uses enriched uranium as fuel. Ordinary or light water is used here as a coolant and moderator. Such reactors are called light water, there are two types of them. In the first, the steam used to turn the turbines is generated in an active zone called a boiling water reactor. In the second, steam generation takes place in the external circuit, which is connected to the primary circuit through heat exchangers and steam generators. This reactor began to be developed in the fifties of the last century, the basis for them was the US army programs. At the same time, at about the same time, the Soyuz developed a boiling water reactor, in which a graphite rod acted as a moderator.

It is the type of reactor with a moderator of this type that has found application in practice. We are talking about a gas-cooled reactor. Its history began in the late forties, early fifties of the XX century, initially the development of this type was used in the production of nuclear weapons. In this regard, two types of fuel are suitable for it, these are weapons-grade plutonium and natural uranium.

The latest project, which was accompanied by commercial success, was a reactor where heavy water is used as a coolant, and natural uranium, already familiar to us, is used as fuel. Initially, several countries designed such reactors, but as a result, their production was concentrated in Canada, which is the reason for the presence of massive deposits of uranium in this country.

Thorium nuclear power plants - the energy of the future?

History of improvement of types of nuclear reactors

The reactor of the first nuclear power plant on the planet was a very reasonable and viable design, which was proved during the long-term and flawless operation of the station. Among its constituent elements were:

- side water protection;

- masonry casing;

- top cover;

- prefabricated collector;

- fuel channel;

- top plate;

- graphite masonry;

- bottom plate;

- distribution manifold.

Stainless steel was chosen as the main structural material for TVEL cladding and technological channels; at that time, it was not known about zirconium alloys, which could be suitable for operation at a temperature of 300°C. The cooling of such a reactor was carried out with water, while the pressure under which it was supplied was 100 at. In this case, steam was released with a temperature of 280°C, which is quite a moderate parameter.

The channels of a nuclear reactor were designed in such a way that it was possible to completely replace them. This is due to the limitation of the resource, which is due to the time spent by the fuel in the activity zone. The designers found no reason to expect that the structural materials located in the zone of activity under irradiation will be able to work out their entire resource, namely about 30 years.

As for the design of the TVEL, it was decided to adopt a tubular version with a one-sided cooling mechanism

This reduced the likelihood that fission products would enter the circuit in the event of a fuel element failure. To regulate the temperature of the TVEL cladding, a fuel composition of a uranomolybdenum alloy was used, which had the form of grains dispersed by means of a warm-water matrix. The nuclear fuel processed in this way made it possible to obtain highly reliable fuel elements. capable of operating under high thermal loads.

The infamous Chernobyl nuclear power plant can serve as an example of the next round in the development of peaceful nuclear technologies. At that time, the technologies used in its construction were considered the most advanced, and the type of reactor the most modern in the world. We are talking about the RBMK-1000 reactor.

The thermal power of one such reactor reached 3200 MW, while it has two turbogenerators, the electric power of which reaches 500 MW, so one power unit has an electric power of 1000 MW. Enriched uranium dioxide was used as fuel for the RBMK. In the initial state before the start of the process, one ton of such fuel contains about 20 kg of fuel, namely uranium - 235. With stationary loading of uranium dioxide into the reactor, the mass of the substance is 180 tons.

But the loading process is not a bulk, fuel elements are placed in the reactor, already well known to us TVEL. In fact, they are tubes, for the creation of which a zirconium alloy is used. As contents, they contain uranium dioxide tablets, which have a cylindrical shape. In the reactor activity zone, they are placed in fuel assemblies, each of which combines 18 fuel elements.

There are up to 1700 such assemblies in such a reactor, and they are placed in a graphite masonry, where technological channels of a vertical shape are specially designed for these purposes. It is in them that the coolant circulates, the role of which, in the RMBC, is played by water. A whirlpool of water occurs when exposed to circulation pumps, of which there are eight pieces. The reactor is located inside the shaft, and the graphic masonry is located in a cylindrical body 30 mm thick. The support of the entire apparatus is a concrete base, under which there is a pool - a bubbler, which serves to localize the accident.

The third generation of reactors uses heavy water

The main element of which is deuterium. The most common design is called CANDU, it was developed in Canada and is widely used around the world. The core of such reactors is located in a horizontal position, and cylindrical tanks play the role of a heating chamber. The fuel channel stretches through the entire heating chamber, each of these channels has two concentric tubes. There are outer and inner tubes.

In the inner tube, the fuel is under coolant pressure, which makes it possible to additionally refuel the reactor during operation. Heavy water with formula D20 is used as a moderator. During a closed cycle, water is pumped through the pipes of the reactor containing bundles of fuel. As a result of nuclear fission, heat is released.

The cooling cycle when using heavy water consists in passing through steam generators, where ordinary water boils from the heat released by heavy water, as a result of which high-pressure steam is formed. It is distributed back to the reactor, resulting in a closed cooling cycle.

It was along this path that the step-by-step improvement of the types of nuclear reactors that were and are being used in various countries of the world took place.

What is a nuclear power plant?

A nuclear power plant or nuclear power plant is a thermal power plant in which the heat source is a nuclear reactor. Typically, in all conventional thermal power plants, the heat is used to generate steam, which drives a steam turbine connected to an electric generator, which generates electricity. As of April 23, 2014, the IAEA has reported on the operation of 435 nuclear power reactors in 31 countries around the world. Nuclear power plants are generally considered to be base load plants because the cost of fuel is a small part of the cost of production. their operating costs, Maintenance and fuel, along with hydro, are at the lower end of the range, making them suitable for the role of baseload electricity providers. However, the costs of spent fuel disposal are quite volatile.

History of the nuclear industry

For the first time in history, electricity was generated using a nuclear reactor on September 3, 1948, at the X-10 Graphite Reactor in Oak Ridge, Tennessee, United States of America. This reactor was the prototype of the first nuclear power plant and produced enough electricity to power an incandescent lamp. The second larger experiment was carried out on December 20, 1951 at the EBR-I experimental station near Arco, Idaho in the United States of America. On June 27, 1954, the world's first nuclear power plant began operating in the Soviet city of Obninsk to generate electricity for the energy system. The world's first full-scale power plant Calder Hall was launched in England on October 17, 1956. The world's first full-scale power plant, Shippingport, designed solely for the production of electricity (Calder Hall was also designed for the production of plutonium), was connected to the grid on December 18, 1957 in the United States of America.

How a nuclear power plant works

The conversion into electrical energy occurs indirectly, as in conventional thermal power plants. The fission of the nucleus of an atom in a nuclear reactor heats the reactor coolant. The coolant can be water or gas, or even liquid metal, depending on the type of reactor. The reactor coolant then passes into the steam generator and heats water to produce steam. The pressurized steam is then typically fed into a multi-stage steam turbine. After the steam turbine has expanded and partially condensed the steam, the remaining steam condenses in the condenser. The condenser is a heat exchanger that is connected to a secondary cooling circuit such as a river or cooling tower. The water is then pumped back into the steam generator and the cycle starts again. The steam-water cycle corresponds to the Rankine cycle.

nuclear reactor nuclear power plant

The nuclear reactor is the heart of the station. In its central part, in the reactor core, heat is generated as a result of the controlled fission of the atomic nucleus. This heat heats the coolant as it is pumped through the reactor and thus draws energy out of the reactor. The heat from nuclear fission is used to produce steam, which is passed through turbines, which in turn power electrical generators.

Nuclear reactors typically use uranium as the fuel for the chain reaction. Uranium is a very heavy metal found in abundance in seawater in most of the rocks on Earth. Naturally occurring uranium occurs as two different isotopes: uranium-238 (U-238), which makes up 99.3% of natural uranium, and uranium-235 (U-235), which accounts for about 0.7% of naturally occurring uranium . Isotopes are atoms of the same element with different numbers of neutrons. So U-238 has 146 neutrons and U-235 has 143 neutrons. Different isotopes have different behavior patterns. For example, U-235 is fissile, meaning that it fissions easily and releases a lot of energy, making it ideal for nuclear power. On the other hand, U-238 does not have this property despite being the same element. Different isotopes also have different half-lives. The half-life is the amount of time it takes for half of a sample of a radioactive element to decompose. U-238 has a longer half-life than U-235, so it takes longer to degrade. This also means that U-238 is less radioactive than U-235.

Since nuclear fission creates radioactivity, the reactor core is surrounded by a protective shield. This shell absorbs radiation and prevents the release of radioactive material into the environment. In addition, many reactors are equipped with a concrete dome to protect the reactor from both internal accidents and external influences.

Steam turbine nuclear power plant

The purpose of a steam turbine is to convert the heat contained in the steam into mechanical energy. The machine room with the steam turbine is, as a rule, structurally separated from the building of the main nuclear reactor. The buildings of the turbine hall and the nuclear reactor are located so that in the event of a turbine explosion during operation, iron fragments do not reach the reactor.

In the case of a pressurized water-cooled nuclear reactor, the steam turbine is separated from the nuclear system. To detect a leak in the steam generator and thus radioactive water entering the primary circuit, a radiometer is installed that monitors the steam leaving the steam generator. In contrast, in boiling water reactors, radioactive water passes through a steam turbine, so that the turbine is part of the radiographically controlled area of the nuclear power plant.

Nuclear Power Plant Generator

The generator converts the mechanical energy of the turbine into electrical energy. Low-voltage synchronous alternators of high rated power are used.

NPP cooling system

The cooling system removes heat from the reactor core and transports it to another area of the plant, where the thermal energy can be used to generate electricity or perform other useful work. Typically, the hot heat transfer fluid is used as the heat source for the boiler, and pressurized steam from the boiler drives one or more steam turbines of electrical generators.

NPP Safety Valves

In the event of an emergency, can be used safety valves to prevent rupture of pipes or explosion of the reactor. The valves are designed in such a way that they can detect the slightest increase in pressure of all supplied energy carriers. In the case of a boiling water reactor, the steam is sent to the pressure reduction chamber and condensed there. The chambers in the heat exchanger are connected to an intermediate cooling circuit.

Nuclear power plant feed water pump

The water level in the steam generator and nuclear reactor is controlled by a feed water system. The feed water pump has the task of drawing water from the condensate treatment system, increasing the pressure and directing it to the steam generators (in the case of a pressurized water reactor) or directly to the reactor (for boiling water reactors).

NPP emergency power supply

Most nuclear power plants need two different power sources, namely off-site auxiliary transformers of the feeder stations, which are sufficiently separated in the distribution substation and can be fed from several power lines. In addition, in some nuclear power plants, the turbine generator can supply the power plant's auxiliary needs during plant operation using auxiliary transformers, which release electricity from the generator busbars before it reaches the step-up transformer (these plants also have plant auxiliary transformers that receive electricity from external power sources directly from the distribution substation). Even with two redundant power supplies, full power supply from external sources is possible. Nuclear power plants are equipped with an emergency power source.

Specialists at a nuclear power plant

- nuclear engineers

- Nuclear reactor operators

- Dosimetry service workers

- Emergency response team personnel

- Permanent inspectors of the Nuclear Regulatory Commission

In the United States of America and Canada, power station workers, with the exception of management, qualified personnel (such as engineers), and security personnel, may be members of either the International Electrical Workers Union (IBEW) or the Utility Workers Union of America (UWUA), or one from various trade unions or organizations of workers representing the interests of machinists, workers, boilermakers, assemblers, metalworkers, etc.

NPP costs

The economics of new nuclear power plants is a contentious issue, and multibillion-dollar investments depend on the choice of energy source. Nuclear power plants typically have high capital costs but low direct fuel costs associated with the costs of extraction, processing, fuel use, and internalized spent fuel storage costs. Thus, comparison with other methods of power generation is highly dependent on assumptions about the timing of construction and financing of capital investments for nuclear plants. Under the Price-Anderson Act in the United States, cost estimates include the cost of decommissioning a power plant and storing or processing nuclear waste. Fourth generation reactors are currently being developed with the prospect that all spent nuclear fuel ("nuclear waste") could potentially be reprocessed using future reactors to completely close the nuclear fuel cycle. Currently, however, there is no effective bulk disposal of waste from nuclear power plants, and the method of on-site temporary storage is still used in almost all power plants due to problems with the construction of permanent waste storage facilities. Only Finland has plans to build permanent storage facilities, so globally the long-term costs of waste storage are uncertain.

On the other hand, construction costs or capital expenditures towards global warming mitigation measures such as a carbon tax or carbon trading increasingly favor the economics of nuclear power. There is hope of achieving greater efficiency through more advanced reactor designs. Generation III Reactors are promised to have at least 17% lower fuel consumption and lower capital costs, while futuristic Generation Four Reactors promise 10,000-30,000% greater fuel efficiency and nuclear waste disposal.

In Eastern Europe, a number of long-standing projects are struggling to find funding, notably Belene in Bulgaria and additional reactors at Cernavoda in Romania, and some potential sponsors have "left the station". The availability of cheap gas and the relative security of its future supply is also a major challenge for nuclear projects.

Analyzing the economics of nuclear power, one must take into account who bears the risks associated with the uncertainty of the future. To date, all operating nuclear power plants have been built by state-owned or state-regulated utility monopolies, where many of the risks associated with construction costs, operating performance, fuel prices and other factors have been borne by consumers rather than suppliers. Many countries have already liberalized the electricity market, where these risks, as well as the risk of the emergence of cheaper competitors before the payback of capital expenditures, fall on the shoulders of suppliers and plant operators, and not on consumers, which leads to a significant change in the assessment of the economics of new nuclear power plants.

Due to the Fukushima I accident in 2011, costs are likely to increase for existing and new nuclear plants due to increased requirements for on-site storage of spent fuel and increased design hazards. However, many projects, such as the AP1000 currently under construction, use passive cooling systems for nuclear safety, unlike Fukushima I, which needs an active cooling system, and this greatly reduces the need to spend more on redundant redundant safety equipment.

NPP safety

In his book Normal Accidents, Charles Perrow says that numerous and unexpected failures are built into complex and dense related systems nuclear reactors. Such accidents are inevitable and cannot be prevented. An interdisciplinary team from the Massachusetts Institute of Technology (MIT) has calculated that, given the expected growth in nuclear power, at least four serious nuclear accidents can be expected between 2005 and 2055. However, the MIT study does not take into account security improvements since the 1970s. From 1970 to the present, there have been five major accidents (core damage) in the world: one at the Three Mile Island nuclear power plant in 1979, one at the Chernobyl nuclear power plant in 1986, and three at the Fukushima-1 nuclear power plant in 2011, which corresponds to start of operation of Second Generation Reactors. On average, there is one serious accident every eight years worldwide.

Modern designs of nuclear reactors have been improved many times in terms of safety since the first generation of nuclear reactors. Nuclear power plants cannot explode like a nuclear bomb because the fuel for uranium reactors is not enriched enough, and nuclear weapons require a precision explosive to force the fuel in a small enough volume to reach a supercritical state. Most reactors require continuous temperature control to prevent the core from melting, which has happened several times due to an accident or natural disaster, releasing radiation and making the environment uninhabitable. Power plants must be protected from the theft of nuclear material (for example, to make a "dirty" nuclear bomb) and from attack by military aircraft (which took place) or enemy missiles, or aircraft hijacked by terrorists.

Nuclear controversy

Discussions about nuclear power are over a contentious issue that arose with the introduction and use of nuclear fission reactors to generate electricity from nuclear fuel for civilian purposes. The discussion about nuclear power reached its peak in the 1970s and 1980s, when it "reached an intensity unprecedented in the history of technological controversy" in some countries.

Proponents argue that nuclear power is a sustainable source of energy that reduces carbon emissions and can improve energy security if its use displaces dependence on imported fuel. Proponents promote the idea that nuclear power generates virtually no air pollution, unlike the main viable alternative, fossil fuels. Proponents also believe that nuclear power is the only viable option for achieving energy independence in most Western countries. They emphasize that the risks of waste storage are low and can be further reduced by using the latest technologies in new reactors, and operational safety reports in the Western world indicate that nuclear power plants are in excellent condition compared to other major types of power plants.

Opponents argue that nuclear power poses many threats to people and environment and also that the costs do not justify the benefits. Threats include health risks and environmental damage from uranium mining, processing and transportation, the risk of nuclear proliferation or sabotage, and the unresolved issue of radioactive nuclear waste. Another environmental problem is the discharge of hot water into the sea. Hot water changes the environmental conditions for marine life. They also argue that the reactors themselves are extremely complex machines, where many processes can and do not go according to plan, which has already led to many serious nuclear accidents. Critics do not believe that these risks can be mitigated by new technologies. They argue that when looking at all the energy-intensive steps in the nuclear fuel chain, from uranium mining to nuclear decommissioning, nuclear power is not a low-carbon source of electricity. Those countries that do not have uranium mines cannot achieve energy independence through existing nuclear power technologies. Actual construction costs often exceed estimates, and spent fuel storage costs do not have a clear time frame.

NPP nuclear fuel processing

Nuclear fuel reprocessing technology was developed for the chemical separation and recovery of fissile plutonium from irradiated nuclear fuel. Recycling serves several purposes, the relative importance of which has changed over time. Initially, reprocessing was done solely to extract plutonium for the production of nuclear weapons. With the commercialization of nuclear power, spent plutonium is being processed back into mixed oxide nuclear fuel for thermal reactors. Reprocessed uranium, which makes up the majority of spent fuel material, can in principle also be reused as fuel, but this is only economically viable when uranium prices are high or disposal is expensive. Finally, a breeder reactor can use not only reprocessed plutonium and uranium in spent fuel, but all actinides, completing the nuclear fuel cycle and potentially multiplying the energy extracted from natural uranium by more than 60 times.

Nuclear fuel reprocessing reduces the volume of highly radioactive waste, but does not in itself reduce radioactivity or heat generation, and therefore does not eliminate the need to store waste in geological formations. Reprocessing is politically controversial due to its potential to promote nuclear proliferation, potential vulnerability to nuclear terrorism, political issues in site selection (an issue that applies equally to direct disposal of spent nuclear fuel), and its high cost compared to a single fuel cycle. In the United States of America, the Obama administration backtracked on President Bush's plans for industrial-scale recycling and returned to a recycling-focused program linked to scientific research.

Accidents at nuclear power plants

The Vienna Convention on Civil Liability for Nuclear Damage established an international framework for nuclear liability. However, the states with the most nuclear power plants in the world, including the United States, Russia, China and Japan, are not parties to international conventions on nuclear liability.

In the US, nuclear or radiation incident insurance is covered (for facilities licensed through 2025) under the Price-Anderson Nuclear Industry Assurance Act.

In accordance with the Energy Policy of the United Kingdom through the Nuclear Installations 1965 regulates liability for nuclear damage, for which the British license holder for nuclear power is liable. The law requires the responsible operator to pay damages up to £150 million within ten years of the incident. Ten years from now, for the next twenty years, the government is responsible for this commitment. The government is also responsible for an additional limited interstate obligation (about £300 million) under international conventions (the Paris Convention on Third Party Liability in the Field of Nuclear Energy and the Brussels Convention Supplementary to the Paris Convention).

NPP decommissioning

The decommissioning of nuclear facilities is the dismantling of a nuclear power plant and the decontamination of the site to a state that does not pose a radiation hazard to the civilian population. The main difference from the dismantling of other types of power plants is the presence of radioactive material, the removal and transfer of which to the waste storage requires special precautions.

Generally speaking, nuclear power plants have been designed with a service life of about 30 years. The new stations are designed with a service life of 40 to 60 years. One of the wear factors is the deterioration of the reactor screen under the action of neutron irradiation.

Decommissioning involves many administrative and technical measures. It includes a complete cleanup of radioactivity and the absolute demolition of the station. Once a facility has been decommissioned, it should no longer pose any risk of a radioactive accident or be hazardous to the health of its visitors. After the facility is completely decommissioned, it is released from regulatory control, and the plant licensee is no longer responsible for its nuclear safety.

Historical accidents at nuclear power plants

The nuclear industry claims that new technology and controls have made nuclear plants much safer, but since the Chernobyl disaster in 1986 and through 2008, there have been 57 minor accidents, two-thirds of which were in the US. The French Atomic Energy Agency (CEA) has concluded that technical innovation cannot completely eliminate the risk human factor in the operation of a nuclear power plant.

According to Benjamin Sovacool, in 2003 an interdisciplinary team at the Massachusetts Institute of Technology (MIT) calculated that, given the expected growth in nuclear power, at least four serious nuclear accidents could be expected between 2005 and 2055. However, the MIT study does not account for security improvements since the 1970s.

Advantages of nuclear energy

Nuclear plants are used mainly for base load due to economic considerations. The cost of fuel to operate a nuclear power plant is less than the cost of fuel to operate a coal-fired or gas-fired power plant. The work of the nuclear power plant is not full power is not economically justified.

However, in France, nuclear plants operate predominantly in load-following mode, although "it is commonly believed that this is not an ideal economic situation for nuclear plants." Block A at Byblis Nuclear Power Plant in Germany is designed to increase and decrease power generation by 15% per minute from 40% to 100% of its rated capacity. Boiling water reactors typically have load following capability accomplished by varying the recirculated water flow.

Future Power Plant Projects

A new generation of designs for nuclear power plants, known as Generation IV reactors, is the subject of active research. Many of these new projects are specifically trying to make nuclear fission reactors cleaner, safer, and/or less risky for nuclear proliferation. Passively safe plants can be built (for example, an economical simplified boiling water nuclear reactor), while the goal of research is to develop reactors with almost complete exclusion of the influence of the human factor on them. Fusion reactors, which are still in their early stages of development, have reduced or eliminated some of the risks associated with nuclear fission.

Two European Pressurized Water Reactors (EPRs) with a total capacity of 1600 MW are being built in Europe and two are being built in China. The reactors are a joint project of the French corporation AREVA and the German Siemens AG and will be the largest reactors in the world. One EPR is located in Olkiluoto in Finland and is part of the Olkiluoto NPP. The reactor was originally scheduled to start up in 2009, but the launch has been repeatedly delayed and, as of September 2014, has been pushed back to 2018. Preparatory work for EPR at the Flamanville Nuclear Power Plant in Flamanville, Manche in France began in 2006 with a planned completion date of 2012. The launch of the French reactor was also delayed, and according to forecasts in 2013, it was scheduled to start in 2016. Two Chinese EPRs are part of the Taishan Nuclear Power Plant in Taishan, Guangdong. The launch of the Taishan NPP reactors was scheduled for 2014 and 2015, but was delayed until 2017.

As of March 2007, seven nuclear power plants in India and five in China are under construction.

Gulf Power said in November 2011 that by the end of 2012 it hopes to complete the purchase of 4,000 acres of land north of Pensacola, Florida to build a possible nuclear power plant.

In 2010, Russia commissioned a floating nuclear power plant. The £100 million vessel Akademik Lomonosov is the first of seven stations that will provide Russia's remote regions with vital energy resources.

With no nuclear power plants in 2011, Southeast Asian countries will have a total of 29 nuclear power plants by 2025: Indonesia will have 4 nuclear power plants, Malaysia will have 4, Thailand will have 5, and Vietnam will have 16.

In 2013, China had 32 nuclear reactors under construction, the largest number in the world.

Between 2016 and 2019, the expansion of two nuclear power plants in the United States of America, namely the Vogtle nuclear power plant in Georgia and the VC Summer nuclear power plant in South Carolina, is scheduled to be completed. The two new reactors at the Vogtle nuclear power plant and the two new reactors at the VC Summer nuclear power plant are the first nuclear power plant projects in the United States of America since the Three Mile Island accident in 1979.

The UK government has approved the construction of the Hinckley Point C nuclear power plant.

Several countries have embarked on a thorium nuclear program. Thorium occurs in nature four times more often than uranium. More than 60% of thorium ore deposits - monazite - are located in five countries: Australia, USA, India, Brazil and Norway. These thorium resources are sufficient to meet current energy needs for thousands of years. The thorium fuel cycle is capable of generating nuclear power with a lower yield of radiotoxic waste than the uranium fuel cycle.

Nuclear energy is used in thermal power engineering, when energy is obtained from nuclear fuel in reactors in the form of heat. It is used to generate electricity in nuclear power plants (NPP), for power plants of large sea vessels, for desalination of sea water.

Nuclear energy owes its appearance, first of all, to the nature of the neutron discovered in 1932. Neutrons are part of all atomic nuclei, except for the hydrogen nucleus. Bound neutrons in the nucleus exist indefinitely. In their free form, they are short-lived, since they either decay with a half-life of 11.7 minutes, turning into a proton and emitting an electron and a neutrino, or are quickly captured by the nuclei of atoms.

Modern nuclear power is based on the use of energy released during the fission of a natural isotope uranium-235. At nuclear power plants, a controlled nuclear fission reaction is carried out in nuclear reactor. According to the energy of neutrons that produce nuclear fission, distinguish between thermal and fast neutron reactors.

The main unit of a nuclear power plant is a nuclear reactor, the diagram of which is shown in fig. 1. Energy is obtained from nuclear fuel, and then it is transferred to another working fluid (water, metallic or organic liquid, gas) in the form of heat; then it is converted into electricity in the same way as in conventional ones.

They control the process, maintain the reaction, stabilize the power, start and stop the reactor using special mobile control rods 6 and 7 from materials that intensively absorb thermal neutrons. They are driven by a control system 5 . Actions control rods are manifested in a change in the power of the neutron flux in the core. By channels 10 water circulates, cooling the biological protection concrete

The control rods are made of boron or cadmium, which are thermally, radiation and corrosion resistant, mechanically strong, and have good heat transfer properties.

Inside a massive steel case 3 there is a basket 8 with fuel elements 9 . The coolant enters through the pipeline 2 , passes through the core, washes all fuel elements, heats up and through the pipeline 4 enters the steam generator.

Rice. 1. Nuclear reactor

The reactor is placed inside a thick concrete biological containment device. 1 , which protects the surrounding space from the flow of neutrons, alpha, beta, gamma radiation.

Fuel elements (fuel rods) is the main part of the reactor. A nuclear reaction directly takes place in them and heat is released, all other parts serve to insulate, control and remove heat. Structurally, fuel elements can be made of rod, plate, tubular, spherical, etc. Most often they are rod, up to 1 meter long, 10 mm in diameter. They are usually assembled from uranium pellets or from short tubes and plates. Outside, the fuel rods are covered with a corrosion-resistant, thin metal sheath. Zirconium, aluminum, magnesium alloys, as well as alloyed stainless steel are used for the shell.

The transfer of heat released during a nuclear reaction in the reactor core to the working fluid of the engine (turbine) of power plants is carried out according to single-loop, double-loop and three-loop schemes (Fig. 2).

Rice. 2. Nuclear power plant

a - according to a single-circuit scheme; b - according to the two-circuit scheme; c - according to the three-circuit scheme

1 - reactor; 2, 3 - biological protection; 4 - pressure regulator; 5 - turbine; 6 - electric generator; 7 - capacitor; 8 - pump; 9 - reserve capacity; 10 – regenerative heater; 11 – steam generator; 12 - pump; 13 - intermediate heat exchanger

Each circuit is a closed system. Reactor 1 (in all thermal circuits) placed inside the primary 2 and secondary 3 biological defenses. If the nuclear power plant is built according to a single-circuit thermal scheme, the steam from the reactor through the pressure regulator 4 enters the turbine 5 . The turbine shaft is connected to the generator shaft 6 in which electric current is generated. The exhaust steam enters the condenser, where it is cooled and completely condensed. Pump 8 directs condensate to a regenerative heater 10 , and then it enters the reactor.

With a two-circuit scheme, the coolant heated in the reactor enters the steam generator 11 , where heat is transferred by surface heating to the coolant of the working fluid (feed water of the secondary circuit). In pressurized water reactors, the coolant in the steam generator is cooled by approximately 15 ... 40 ° C and then by a circulation pump 12 back to the reactor.

With a three-loop scheme, the coolant (usually liquid sodium) from the reactor is sent to an intermediate heat exchanger 13 and from there by the circulation pump 12 returns to the reactor. The coolant in the secondary circuit is also liquid sodium. This circuit is not irradiated and therefore non-radioactive. Sodium of the second circuit enters the steam generator 11 , gives off heat to the working fluid, and then the circulation pump is sent back to the intermediate heat exchanger.

The number of circulation circuits determines the type of reactor, the coolant used, its nuclear-physical properties, and the degree of radioactivity. The single-loop scheme can be used in boiling water reactors and in gas-cooled reactors. The most widespread double circuit when used as a heat carrier of water, gas and organic liquids. The three-circuit scheme is used at nuclear power plants with fast neutron reactors using liquid metal coolants (sodium, potassium, sodium-potassium alloys).

Nuclear fuel can be uranium-235, uranium-233 and plutonium-232. Raw materials for obtaining nuclear fuel - natural uranium and thorium. During the nuclear reaction of one gram of fissile material (uranium-235), energy equivalent to 22×10 3 kWh (19×10 6 cal) is released. To obtain this amount of energy, it is necessary to burn 1900 kg of oil.

Uranium-235 is readily available, its energy reserves are about the same as fossil fuels. However, using nuclear fuel with such low efficiency as it is now, the available uranium sources will be depleted in 50-100 years. At the same time, there are practically inexhaustible "deposits" of nuclear fuel - this is uranium dissolved in sea water. It is hundreds of times more abundant in the ocean than on land. The cost of obtaining one kilogram of uranium dioxide from sea water is about $60-80, and in the future it will drop to $30, while the cost of uranium dioxide produced in the richest deposits on land is $10-20. Therefore, after some time, the costs on land and "on sea water" will become of the same order.

The cost of nuclear fuel is about half that of fossil coals. At coal-fired power plants, 50-70% of the cost of electricity falls to the share of fuel, and at nuclear power plants - 15-30%. A modern thermal power plant with a capacity of 2.3 million kW (for example, Samara GRES) daily consumes about 18 tons of coal (6 trains) or 12 thousand tons of fuel oil (4 railway composition). The nuclear one, of the same power, consumes only 11 kg of nuclear fuel during the day, and 4 tons during the year. However, a nuclear power plant is more expensive than a thermal one in terms of construction, operation, and repair. For example, the construction of a nuclear power plant with a capacity of 2–4 million kW costs approximately 50–100% more than a thermal one.

It is possible to reduce capital costs for NPP construction by:

- standardization and unification of equipment;

- development of compact reactor designs;

- improvement of management and regulation systems;

- reducing the duration of the shutdown of the reactor for refueling.

An important characteristic of nuclear power plants (nuclear reactor) is the efficiency of the fuel cycle. To improve the economy of the fuel cycle, you should:

- to increase the depth of nuclear fuel burnup;

- raise the breeding ratio of plutonium.

With each fission of the uranium-235 nucleus, 2-3 neutrons are released. Of these, only one is used for further reaction, the rest are lost. However, it is possible to use them for the reproduction of nuclear fuel by creating fast neutron reactors. When the reactor is operating on fast neutrons, it is possible to simultaneously obtain approximately 1.7 kg of plutonium-239 for 1 kg of burned uranium-235. In this way, the low thermal efficiency of nuclear power plants can be covered.

Fast neutron reactors are ten times more efficient (in terms of the use of nuclear fuel) than fuel neutron reactors. They have no moderator and use highly enriched nuclear fuel. Neutrons emitted from the core are absorbed not by structural materials, but by uranium-238 or thorium-232 located around.

In the future, the main fissile materials for nuclear power plants will be plutonium-239 and uranium-233, obtained respectively from uranium-238 and thorium-232 in fast neutron reactors. The conversion of uranium-238 into plutonium-239 in reactors will increase the resources of nuclear fuel by about 100 times, and thorium-232 into uranium-233 by 200 times.

On fig. Figure 3 shows a diagram of a fast neutron nuclear power plant.

Distinctive features of a nuclear power plant on fast neutrons are:

- the change in the criticality of a nuclear reactor is carried out by reflecting part of the fission neutrons of nuclear fuel from the periphery back to the core using reflectors 3 ;

- reflectors 3 can rotate, changing the leakage of neutrons and, consequently, the intensity of fission reactions;

- nuclear fuel is reproduced;

- removal of excess thermal energy from the reactor is carried out using a cooler-radiator 6 .

Rice. 3. Scheme of a nuclear power plant on fast neutrons:

1 - fuel elements; 2 – renewable nuclear fuel; 3 – fast neutron reflectors; 4 - nuclear reactor; 5 - consumer of electricity; 6 - refrigerator-emitter; 7 - converter of thermal energy into electrical energy; 8 - radiation protection.

Converters of thermal energy into electrical energy

According to the principle of using thermal energy generated by a nuclear power plant, converters can be divided into 2 classes:

- machine (dynamic);

- machineless (direct converters).

In machine converters, a gas turbine plant is usually connected to the reactor, in which the working fluid can be hydrogen, helium, helium-xenon mixture. The efficiency of converting heat supplied directly to the turbogenerator into electricity is quite high - the efficiency of the converter η = 0,7-0,75.

A diagram of a nuclear power plant with a dynamic gas turbine (machine) converter is shown in fig. four.

Another type of machine converter is a magnetogasdynamic or magnetohydrodynamic generator (MGDG). A diagram of such a generator is shown in fig. 5. The generator is a channel of rectangular cross section, two walls of which are made of a dielectric, and two of which are made of an electrically conductive material. An electrically conductive working fluid moves through the channels - liquid or gaseous, which is penetrated by a magnetic field. As you know, when a conductor moves in a magnetic field, an EMF arises, which along the electrodes 2 transferred to the consumer of electricity 3 . The energy source of the working heat flow is the heat released in the nuclear reactor. This thermal energy is spent on the movement of charges in a magnetic field, i.e. is converted into the kinetic energy of the current-carrying jet, and the kinetic energy is converted into electrical energy.

Rice. 4. Scheme of a nuclear power plant with a gas turbine converter:

1 - reactor; 2 – circuit with liquid metal coolant; 3 – heat exchanger for heat supply to gas; 4 - turbine; 5 - electric generator; 6 - compressor; 7 - radiator-radiator; 8 – heat removal circuit; 9 - circulation pump; 10 - heat exchanger for heat removal; 11 - heat exchanger-regenerator; 12 - circuit with the working fluid of the gas turbine converter.

Direct converters (machineless) of thermal energy into electrical energy are divided into:

- thermoelectric;

- thermionic;

- electrochemical.

Thermoelectric generators (TEGs) are based on the Seebeck principle, which means that in a closed circuit consisting of dissimilar materials, a thermoelectric power arises if a temperature difference is maintained at the points of contact of these materials (Fig. 6). To generate electricity, it is advisable to use semiconductor TEGs, which have a higher efficiency, while the temperature of the hot junction must be brought up to 1400 K and higher.

Thermionic converters (TEC) make it possible to obtain electricity as a result of the emission of electrons from a cathode heated to high temperatures (Fig. 7).

Rice. 5. Magnetogasdynamic generator:

1 – magnetic field; 2 - electrodes; 3 - consumer of electricity; 4 - dielectric; 5 - conductor; 6 - working fluid (gas).

Rice. 6. Scheme of thermoelectric generator operation

Rice. 7. Scheme of operation of the thermionic converter

To maintain the emission current, heat is supplied to the cathode Q one . The electrons emitted by the cathode, having overcome the vacuum gap, reach the anode and are absorbed by it. During the "condensation" of electrons at the anode, energy is released equal to the work function of electrons with the opposite sign. If we ensure a continuous supply of heat to the cathode and its removal from the anode, then through the load R direct current will flow. Electron emission proceeds efficiently at cathode temperatures above 2200 K.

Safety and reliability of NPP operation

One of the main issues in the development of nuclear energy is to ensure the reliability and safety of nuclear power plants.

Radiation safety is ensured by:

- the creation of reliable structures and devices for the biological protection of personnel from exposure to radiation;

- purification of air and water leaving the NPP premises beyond its limits;

- extraction and reliable localization of radioactive contamination;

- daily dosimetric control of NPP premises and individual dosimetric control of personnel.

NPP premises, depending on the mode of operation and the equipment installed in them, are divided into 3 categories:

- strict regime zone;

- restricted zone;

- normal mode zone.

Personnel are constantly in the rooms of the third category; these rooms at the station are radiation safe.

Nuclear power plants generate solid, liquid and gaseous radioactive waste. They must be disposed of in such a way that no pollution of the environment is created.

The gases removed from the room during ventilation may contain radioactive substances in the form of aerosols, radioactive dust and radioactive gases. The ventilation of the station is built in such a way that air flows pass from the most “clean” to “polluted”, and cross-flows in the opposite direction are excluded. In all rooms of the station, a complete replacement of air is carried out within no more than one hour.

During the operation of nuclear power plants, the problem of removal and disposal of radioactive waste arises. Fuel elements spent in reactors withstand a certain time in water pools directly at nuclear power plants until stabilization of isotopes with a short half-life occurs, after which the fuel elements are sent to special radiochemical plants for regeneration. There, nuclear fuel is extracted from the fuel rods, and radioactive waste is subject to burial.