If someone thinks that opening a mini cannery is a hopeless project, then he is deeply mistaken. By carefully studying all aspects of this type economic activity it becomes quite clear that this business has excellent chances not only to become profitable in a short time, but also has large-scale prospects for development in the future.

Perspective business ideas

The main advantage of this type of activity today is the fact that absolutely all farmers who grow vegetables experience an acute shortage of sales markets. If, for example, any root crops, including potatoes, carrots or beets, can be sold for a long period of time, then the bulk of vegetables have a shorter shelf life and, accordingly, should be sold as early as possible. Therefore, many farmers are forced to take completely extreme actions, they either completely refuse to grow such perishable products as tomatoes, cucumbers, peppers, or are limited to only very small areas for these crops. But if you give such farms a stable market, which any cannery can do, then things will be completely different.

At the same time, the mini cannery will also be fully provided with raw materials. And it will be quite cheap raw materials, since at the peak of productivity the prices for such agricultural products are minimal.

Another plus of the business idea follows from the above - today the cannery will have practically no competition on the market. There is no need to worry that you will not be able to compete with such giants of the market as Baltimore or Bonduelle, because you don’t have to do this at all. The point is that these famous brands work in our market according to the following scheme: only 4 months a year they are producers, and the rest of the time they act only as importers. And this circumstance is quite realistic to use.

How to do it:

- In the winter season, it is necessary to establish the production of exclusive products, including various pickled vegetables with sauces in the form of ready-made snacks (mushrooms, eggplant, cucumbers, etc.), stews, lecho. The range in this case is limited only by the manufacturer's imagination and features. national cuisine.

- In the cold season, you can retrain for the manufacture of ready-made canned meals, including cereals with vegetables, various salads.

Important. Companies that specialize in the production of salads receive highest profit especially during the winter seasons. But your company will have a significant advantage here too, because “salad” companies produce their products with a minimum shelf life (no more than 3-4 days), while your products will have a shelf life of up to 6 months.

As you can see, such a business has very real prospects, and therefore we can safely proceed to planning the implementation of this idea in life.

Raw material base

Before starting to resolve issues with equipment for the plant, it is necessary to create a reliable raw material base, that is, to conclude cooperation agreements with suppliers and farms.

The first thing you should pay attention to is the quality of vegetables. Different vegetables require different processing approaches in the canning process, and, based on this, their quality characteristics must be carefully considered. So, for example, vegetables such as cabbage, carrots, peppers do not require preservation of integrity during cooking, since they are amenable to mechanical operations such as chopping, boiling, grinding. Whereas green peas, corn, beans and some other crops that are cooked as a whole must retain their shape during heat treatment.

Therefore, an entrepreneur must make sure that farms provide him with only high-quality products and prescribe these conditions in supply contracts. For farmers, such contracts will mean only one thing: a more serious attitude to their own business, updating the technical park, mastering new technologies for processing crops and new varieties of vegetables. And you, as the main buyer of such products, must convince the farmer that his investments will definitely pay off with higher prices for high-quality raw materials and a stable sales market in your face.

Another major problem associated with the raw material base is seasonality. In the climatic conditions of Russia, many crops cannot grow in winter even with greenhouse cultivation, for example, this applies to crops such as peas or corn. However, they are quite convenient to store frozen.

A related question immediately arises: if vegetables are stored frozen, then their cost increases significantly due to the purchase of refrigeration chambers and electricity costs. Will the new costs completely offset all the profits from the sale of products?

Of course not. The selling price of corn in season and in winter are two big differences. If during the harvest period 1 kilogram of corn grains can be sold for a maximum of 25-30 rubles, then in winter frozen corn can be sold without problems at a price of 100-120 rubles per kilogram.

If we are talking about products that have a long shelf life (potatoes, carrots, beets), then everything is even simpler here. To store these products, you can rent a vegetable store and make basic purchases during the harvest season, when the price of products on the market is minimal. Experts do not recommend considering building your own vegetable store, since such an undertaking requires large investments and will pay off only years later.

Competitiveness and sales of products

Second important point The success of the canned vegetable business lies in the presence of stable distribution channels. And here there are two options: creating your own trading network or sale of products in supermarkets and large retail outlets.

most acceptable and effective options is cooperation with large trading companies that operate on the market not only in a certain region, but also in all cities of Russia, which greatly expands the possibilities of any entrepreneur. But, unfortunately, breaking into such a market is almost impossible. Such companies themselves often act as importers of various canned goods, so in fact you will act as a competitor for them, and not a profitable partner. And with all this, they work in the lowest price segment.

But, no matter how strange it may sound, it is quite possible to turn such obvious disadvantages into fat pluses.

What can be done:

- Invite companies to sell your product under their brand name. Buying them from a domestic manufacturer, that is, from you, will be five times more profitable than from foreign companies, so profitability will certainly be the final argument in your favor, especially if the product you offer is really high quality.

- To exclude competition with the products of the company itself, offer a range of products that will differ from those already on the market, but based on the characteristics of the national cuisine of the Slavs. To implement such a task, you will need to hire a professional technologist who will develop a new recipe for canned food, but such expenses will quickly pay for themselves.

Factory equipment

The complex for processing vegetables for a mini plant must have the following technical characteristics:

- processing capacity of raw materials - not less than 100 kg/h, preferably up to 500 kg/h;

- the area of the premises for the installation of the production line is about 100 square meters. m.;

- electricity consumption - up to 70 kW / h, water - up to 1 cu. m/hour;

- state service personnel– about 10-16 people.

A packaging line is also needed. As packaging should be used: glass jars with cork lids, glass bottles, vertical bags, plastic cups, trays.

Packing volume from 0.06 to 10 liters.

Product range

The following list of products should be considered as a range of products.

But at the same time, it is worth immediately making a reservation that, as already mentioned above, an entrepreneur, when choosing an assortment, should focus solely on his personal experience, the state of the market, and the presence of imagination.

- canned vegetables, including vegetable caviar, salads, lecho, sliced and stuffed vegetables in tomato sauce;

- ready-made dinners from vegetables with the addition of meat;

- semi-finished products that must be heated before use (stuffed cabbage, meatballs);

- vegetable purees;

- sauces and vegetable pastes;

- smoothies from fruits and vegetables with the addition of nuts and cereals;

- dried fruits;

- candied fruit, etc.

The cost of a production line for processing vegetables on the market is about 3.5 million rubles.

Production costs and operating income

It is best to calculate the costs and income from activities, taking into account the fact that the main the production cycle is 4 months in the warm season, because when calculating income from additional species earnings (making salads and ready meals) in the winter period, you can get distorted and not entirely accurate information.

For the basic unit of profit in specific example we will take 1 kilogram of frozen peas.

Costs for one production cycle:

- Peas (or any other vegetables) - 120 tons (1 ton of products is processed per shift, 30 tons per month, respectively, 120 tons per 4 months). The purchase price is 2.4 million rubles (the price of 1 ton is 20 thousand rubles).

- Electricity - 30 thousand kW (per shift - 250 kW, per month - 7.5 thousand kW, for 4 months - 30 thousand kW). The cost of electricity is 96 thousand rubles (the price of 1 kW / hour is 3.2 rubles).

- Wage Fund - 1.5 million rubles for 4 months.

- Rent production areas- 1.2 million rubles (100 thousand rubles per month * 12 months).

Total expenses: 5.2 million rubles.

Income from activities:

- The cost of selling 1 ton of peas is 100 thousand rubles.

- The income from the sale of 120 tons of frozen peas is 12 million rubles.

Net profit: 6.8 million rubles.

Return on investment: during the first season of operation (the first 4 months of the season).

Profitability of production: about 40 percent.

Cannery mini-factory is a very profitable business. And the example we have considered is just one more evidence in favor of this statement, so if you have all the necessary prerequisites for putting this idea into practice, it is not possible to doubt the prospects.

This business idea for the manufacture of canned vegetables may seem unpromising and banal. But on closer examination, you will be able to understand that this is not at all the case, and the production of canned vegetables can become a highly profitable business.

The very first advantage of this business is that all farms that specialize in growing vegetables experience a great lack of a market for all their products. If potatoes, beets, carrots and cabbage can be sold for a sufficiently long period, then sweet corn, green peas, tomatoes, cucumbers, sweet and hot peppers are either grown in limited quantities or not grown at all.

The second benefit of this idea relates to competition. It seems almost impossible to get around big companies like Bonduelle and Baltimore. But this is not necessary. In fact, these representatives famous companies in Russia they produce their products only four months a year, the rest of the time they become importers with a limited assortment of all goods. It is this circumstance that can be used by farming:

Before you start buying everything necessary equipment for your mini-factory, you need to create a database of suppliers of the necessary raw materials in advance. The main problem in this case lies in the quality of vegetables. If carrots, potatoes, beets, sweet peppers and cabbage do not require preservation of integrity in canned form, as they are cut, frayed and boiled. That sweet corn, green peas and beans should be of good quality.

In this case, you have only one way out - this is to conclude contracts with large farms for the supply of only the highest quality products. Another problem that is directly related to raw materials is seasonality. As you know, green peas and sweet corn do not grow in winter, but they can be stored frozen. Some believe that the cost of special refrigeration units and the cost of electricity used negate all possible profits from storing frozen vegetables. But that's not the case at all.

Frozen corn is a very valuable commodity that can not only be canned in jars. One kilogram of fresh corn grains will cost about 20 rubles, and the same amount, but already frozen corn in the winter, you can sell for 100 rubles per kilogram.

As for potatoes, cabbage, carrots and other long-term vegetables, in this case there is nothing complicated. You can rent vegetable stores and stock up on these raw materials for the season in accordance with the entire production plan, or you can simply purchase all the necessary raw materials. Building your own vaults is not an option, since such an undertaking requires a large financial investment.

Competitiveness and implementation

Another equally important prerequisite for success in the production of canned vegetables is the search for stable distribution channels. In this case, there are two ways at once: using the network of large trading companies and creating your own network. With the second option, everything should be clear to you - this is the nearest market, represented by supermarkets and small grocery stores, in which you must offer all your products using various marketing tricks. As for large trading companies, in this case the situation is quite different.

It is almost impossible to break into such companies with your product, since for such companies you are a direct competitor. After all, most of them are also importers of various canned vegetables; they stick labels with their own names on cans with vegetables. trademarks. Moreover, all their products have a low cost. If desired, these circumstances can turn for you from a minus to a big plus.

- In order not to compete with the company's products, introduce products that are unusual for the consumer on the market, but at the same time you should be based on traditional Slavic cuisine. It is better to hire a professional technologist who will help you develop the formulation of the product itself, as well as specifications.

- Can be offered big company use your products, but already under their trademark. Since, according to recent studies, in the modern market, the wholesale purchase of canned food from domestically produced vegetables will cost 20% less than imported ones.

Now it's time to move on to the equipment, your initial investment and profits.

Equipment

- Packing line:

Glass bottles - PET and CPP; - Glass jars with a cork lid - Twist-Off;

- vertical packages;

- Packing volume from 0.06 to 10 kg / liter;

- Plastic trays and cups;

Product range

- heated semi-finished products;

Natural canned vegetables: vinaigrettes, salads, stuffed and chopped vegetables in tomato sauce, different types vegetable caviar and stew; - Lunch dishes from vegetables and with the addition of meat;

- tomato paste;

- Mustard, sauces, ketchups;

- Various types of fruit and vegetable purees;

- candied fruits, dried tomatoes;

- Dried vegetables: chopped, whole, powdered;

- Smoothies - vegetable and fruit, with the addition of juice, admixtures of dried fruits, grated cereals or chopped nuts;

- The cost of a whole line of manufactured products without installation and delivery of equipment is approximately 3,225 million rubles.

Costs and profits

The cost-income model is based on a four-month production cycle in the warm season, since it is impossible to accurately calculate all income from alternative types of income (making ready-made meals and salads). For example, let's take a kilogram of frozen corn for a unit of profit, since similar types of canned vegetables in the same weight equivalent are much more expensive.

Basic expenses:

- Electricity consumption for freezing corn is 29 thousand kilowatts. Based on 250 kilowatts per shift (about 9 hours), 7.3 kilowatts per month and 29 kilowatts per four months. The cost of electricity used is 100 thousand rubles.

- Raw materials: any kind of vegetables - 125 tons. Production for one shift - 1 ton of finished products, for one month - 35 tons, for four months - 130 tons. total cost products - 2.5 million rubles.

- Rental of premises (warehouses and manufacturing facility) - 1000 rubles for one month, for one year - 1 million rubles. While the period of sale of certain products varies within one year.

- Wages to employees - 1.2 million rubles. One handyman accounts for 15 thousand rubles. The total number of employees is 16 people plus one marketer and technologist - 30 thousand rubles for each employee.

- The result is 4.8 million rubles.

All the above calculations and figures have been reduced to an average and depend on the specific situation and tasks.

Total profit

The main unit of income in our case is 1 kilogram of frozen corn (or other canned or frozen vegetables). According to the production plan, in just one cycle, 120 tons of frozen corn are obtained, which means that 1 ton of corn will cost 100 rubles, respectively, for 1 kilogram of corn - 100 rubles, 120 tons of corn will cost 12 million rubles.

- General net income- 7.3 million rubles;

- Profitability of the entire production - 50%;

- Payback of the entire production - up to 4 months;

As you may have noticed, the total income is 7 million rubles in just 4 months - this is quite an impressive figure, even if you set aside several million rubles from this amount for various penalties and force majeure, you will still have an impressive profit. In addition, you can use alternative production methods and make good money on it.

The canned food business is quite profitable if it is properly organized. A small plant at home or in a rented space would be the best option.

Features of a business idea

A mini-factory of this specialization does not have high productivity, so when organizing it, you need to focus on the needs of a local buyer. When placing the capacities of a mini-enterprise, it is necessary to pay attention to the availability of raw materials in order to reduce transportation costs. This will reduce the cost of production.

Mini factory for the production of canned food

As a result, it will become competitive with the products of large manufacturers, which have won the trust of many buyers.

A mini-factory can focus on the manufacture of the following varieties of canned food:

To make a profit from such an enterprise, it is necessary to produce products High Quality, which could compete with home-made preparations. It is also worth considering that the level of profitability of such a plant depends on the wealth of buyers.

Another feature of mini-factories is that their mode of operation is seasonal. The production of canned vegetables and fruits takes place in the summer-autumn period, and the sale - in the winter-spring. If desired, you can set up several lines. One of them should be engaged in the production of meat, fish or mushroom products. Such a line can work throughout the whole year.

Necessary equipment

A canning factory can be equipped with a variety of equipment that allows you to get a specific product. Vegetables, fruits, meat and other raw materials should be packed in prepared glass or iron jars. For the needs of a mini-enterprise, you can purchase the following equipment:

Production process

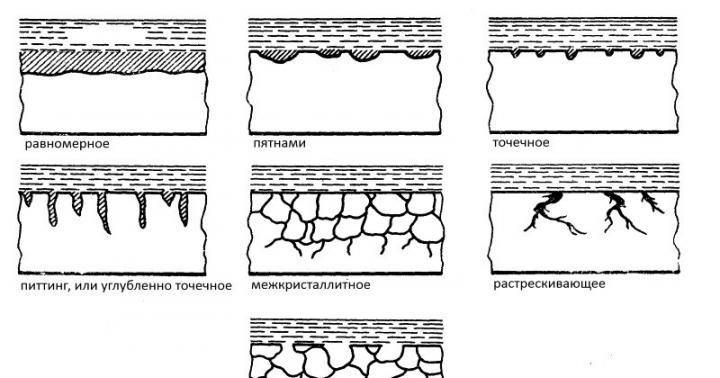

A canned food factory can use the following raw material preservation methods for its work:

- chemical;

- biochemical;

- physical;

- physical and chemical.

The most popular method is the use of preservatives of chemical and biological origin. They are subject to rather high requirements. These substances must be safe, do not change the taste of the products and do not react with the packaging material.

Physical methods include the processing of raw materials using high or low temperatures, ultrasound, ionization, filtration. These include pasteurization, sterilization, freezing and other technological schemes.

Physical and chemical methods are also very popular. In this case, to increase the storage period, use salt, sugar and other preservatives. They are used in combination with pasteurization, sterilization or simple cooking in sealed containers. This type of plant is the most demanded in the market.

In the chemical method of processing raw materials, they use:

- ethanol;

- acetic acid;

- sorbic acid;

- lemon acid;

- benzoic acid.

Their concentration in the finished product must be high to ensure its safety. This can adversely affect the quality, so this method is used in combination with others. Biological preservatives include preparations with bifidum and lactobacilli, lactococci.

Business plan

The payback of such a plant depends on the type and quantity of products produced. It ranges from 0.5 to 2-3 years. Using the example of organizing a line for the production of canned vegetables, let's consider the profitability of an enterprise that operates for 4 months during the harvest season:

- purchase of raw materials. On average, small enterprises at home are able to process no more than 1 ton of vegetables. Therefore, about 120 tons of raw materials will be needed for the entire season. Its cost is 2.4 million rubles;

- electricity. For the operation of all equipment, an average of 240 kW per shift will be required. The demand for the whole season is 28.8 thousand kW worth 100 thousand rubles;

- wage. For effective organization the activities of a mini-enterprise may need from 15 to 20 service personnel. The cost of paying salaries will be 1-1.2 million rubles;

- workshop rental. To install the equipment, you need a room that will be available all year round. Therefore, the average cost of renting it is 1 million rubles.

The total expenses without the purchase of equipment will amount to 4.7 million rubles. After the sale of canned vegetables, you can get about 12 million in income. Net profit will be 7.3 million rubles, profitability - 50%, payback period - 1 season.

Video: Production of canned fish

Food products are classified as cult in our country. Whether this is connected with the memory of the general shortage in the late USSR, or simply with the love of our fellow citizens for tasty and healthy food, who knows. It is only known that even among all the variety of modern food products our people always and everywhere allocate canned food.

Stew is sacred. Almost everyone can tell about the principles of her choice, about her favorite manufacturers. And almost everyone sadly notes that "canned food is not the same." So why not open own production canned goods in order to please compatriots with the “right” product?

Justification of the profitability of the project

Immediately after the crisis of 2008, a strong decline was recorded in the domestic canned food market, but after 2010, production volumes approximately returned to pre-crisis levels. But to this day, the growth of the market by 30% or more is due to imports. With this in mind, well-established domestic production canned food has every chance to occupy a worthy niche in the emerging market.

Most manufacturers are engaged in the production of canned fish. The number of those who chose the “meat” specialization is much smaller. This is due both to the difficulties of purchasing high-quality raw materials, and to the stringent requirements of supervisory authorities.

It is much easier to make canned vegetable products, but leading retailers warn that the demand for it in our country is much lower. Sales volumes of even banal sprats in tomato are much higher than those for the same canned cucumbers.

This situation is associated with the traditionally strong positions of home canning throughout the former CIS, which makes the production of canned vegetables promising only if you do it on an industrial scale.

The situation with canned fruits is even worse: apart from the legendary canned peaches, which have been known to many since the times of the same USSR, their purchases have been in a stage of stable stagnation since 2011.

Market prospects

Experts warn that high profits in this market can only be expected if the manufacturer does something truly unusual. For example, a jar of deer liver pate can cost more than $25 and weigh less than 100 grams.

However, I would like to reiterate that domestic market food products in recent years is experiencing far from better times: the quality of canned food is low, and therefore, to confidently occupy your niche, it will be enough to establish yourself as a responsible and honest manufacturer.

requirements for preservatives

There are several basic methods for the production of canned food, the most common of which are physical and chemical varieties. It is no secret that in modern products of this kind there are many preservatives. In principle, the entire production of canned foods has been sinned with this since they began to be produced on an industrial scale.

Special requirements are imposed on these substances: they must be completely harmless, not violate the original taste of the product, and be excreted from the human body in an unchanged state. Unfortunately, none of the common preservative agents immediately meets all the requirements.

Technology

Regardless of the initial product, the standard production of canned food involves approximately the same steps. At the first of them, the raw materials are carefully examined, their organoleptic characteristics are evaluated. Fruits and vegetables are thoroughly washed and, if necessary, treated with steam and/or UV radiation.

Foreign impurities, excess veins and substandard parts are removed from meat blocks. The same applies to fish. Further technology (the production of canned food must strictly follow it) depends solely on the type of initial product.

As a rule, vegetables and fruits are pickled, for which they are laid out in jars, after which they are poured with a hot or cold (depending on the recipe) solution and sent for sterilization and capping. If we are talking about the production of mashed potatoes or something similar, then the finished product is also packed into containers and goes for sterilization.

Meat and fish are most often stewed in their own juice, and industrial autoclaves are used for this, where even botulism spores are completely destroyed under enormous pressure and temperatures above 100 degrees.

Equipment

Thus, you will need equipment for the production of canning lids, autoclaves, washing equipment, steam generators, conveyor lines, packaging machines, etc. Fortunately, there are currently a huge number of domestic and imported models of this kind of equipment.

Manufacturers offer completely finished and automated lines, the cost of which largely depends on functionality and capacity. For example, the simplest kit for rolling up canned vegetables will cost you 2 million rubles. But to this money you need to add the amount of 450-500 thousand rubles, which will go to the production of marinade. Another 300 thousand will be spent on the purchase of sterilizers.

For about the same money you can buy equipment for the production of canned fish. Additional equipment for cutting fish preserves costs approximately 700-800 thousand rubles. In addition, 100-150 thousand rubles will be eaten up by the production of caps. It is more profitable to produce them yourself, since the quality of third-party products is often very poor.

The finished line for the production of canned meat is already estimated at 10 million, and multifunctional Western machines are sold for 50 million or more. So to say something specific about the costs will not work, because everything depends solely on the direction of your activity. So before you open your own production, you need to carefully approach the planning issues.

SES requirements

As you might guess, they are quite serious. Let's start with the staff. First, each worker without fail there must be a properly completed sanitary book with approvals for the production of food products.

Secondly, each of them must pass a medical examination for employees in a timely manner. processing industry. All employees must have overalls and shoes. Workers can only wear gloves.

As for the shop for the production of canned food, then, firstly, it must be located at a distance of at least 500 meters from the nearest residential building. The building must have a water supply, as well as be connected to the sewer system. In addition, you need to equip a convenient access to the production premises, agree on regular waste disposal. AT summer time they must be cleaned at least once a day.

Please note that any food technology (the production of canned food is no exception) provides for daily disinfection of all work surfaces, so there must be both a supply of disinfectants and containers for storing ready-made solutions on the territory of the enterprise.

Walls and floors are tiled to make these surfaces easier to disinfect. Each batch of raw materials and finished products must have all the necessary certificates of conformity.

Welcome to the business and finance magazine Rabota-Tam.

The production of canned food is a growing branch of the food industry. Therefore, equipment for canning production is offered on the market industrial machinery in a large assortment.

Canned food production line

Production lines are completed depending on the requirements and wishes of the client, who determined the direction of the enterprise: canned meat, vegetables, fish. The price of equipment for canning production depends on the functionality of the equipment, the number of necessary devices, and the manufacturer.

The main composition of equipment for canning production:

- filling and packing machines;

- machines for grinding ingredients;

- machines for hermetic sealing of glass and metal cans;

- automated devices for rolling cans, conveyors;

- automatic dispensers are used to fill jars with liquids: juice, broth;

- washing devices intended for washing containers;

- autoclave - sterilizer.

Autoclaves are essential equipment for the production of canned products.

To buy canning equipment you need to spend more than 3,000,000 rubles. This amount will cost the full equipment of the workshop. But, not every entrepreneur has such an amount. Therefore, you should start with the organization of a mini-workshop. For example, a production that produces only canned meat does not require equipment for processing vegetables or fish.

Equipment for the production of canned meat

The manufacture of canned meat requires compliance with a certain technological process. Empty containers (glass or metal) are washed and scalded, fat is poured into it and spices are added to taste. After adding the meat, the jars are rolled up. Before you put the sealed jars in the autoclave, they should be rinsed. After sterilization in an autoclave, the jars should dry. When the manufacturing process is over, a label is stuck on the canned food.

The manufacture of canned meat requires compliance with a certain technological process. Empty containers (glass or metal) are washed and scalded, fat is poured into it and spices are added to taste. After adding the meat, the jars are rolled up. Before you put the sealed jars in the autoclave, they should be rinsed. After sterilization in an autoclave, the jars should dry. When the manufacturing process is over, a label is stuck on the canned food.

Set of equipment for the production of canned meat:

- devices for rinsing and steaming cans;

- dosing device for filling containers;

- automatic meat dispenser;

- machine for rolling up metal and glassware;

- autoclave sterilizer;

- can washing and drying machine;

- labeling machine.

The cost of the production line varies from 1.5 to 2.5 million rubles. If we add to this list the payment for the premises, the purchase of additional equipment, furniture and payment for employees, then the amount will be quite large. Not always a novice businessman has financial means in such volume.

Used equipment

It is possible to save on the purchase of equipment, but it is desirable that the quality of the finished product does not suffer. Purchasing used equipment for canning production is dangerous because if one of the devices breaks down, the entire manufacturing process can be harmed. Therefore, the inspection of used equipment must be very thorough, and technical documentation carefully studied. But even these actions will not guarantee a long service life of used equipment.

Mini-shop for the production of canned food

This is a fully automated technique with the following advantages:

- affordable cost of equipment;

- ease of installation and operation;

- placement does not require a large area;

- a minimum of employees serving the apparatus;

- compactness of devices;

- mobility;

- high profitability.

When buying equipment, you need to check the availability of certificates and compliance with the requirements of the SES.