Any fuel, when burned, releases heat (energy), quantified in joules or calories (4.3J = 1cal). In practice, to measure the amount of heat that is released during the combustion of fuel, calorimeters are used - complex devices for laboratory use. The heat of combustion is also called the calorific value.

The amount of heat obtained from the combustion of fuel depends not only on its calorific value, but also on its mass.

To compare substances in terms of the amount of energy released during combustion, the value of the specific heat of combustion is more convenient. It shows the amount of heat generated during the combustion of one kilogram (mass specific heat of combustion) or one liter, cubic meter (volume specific heat of combustion) of fuel.

The units of specific heat of combustion of fuel accepted in the SI system are kcal / kg, MJ / kg, kcal / m³, MJ / m³, as well as their derivatives.

The energy value of fuel is determined precisely by the value of its specific heat of combustion. The relationship between the amount of heat generated during the combustion of fuel, its mass and the specific heat of combustion is expressed by a simple formula:

Q = q m, where Q is the amount of heat in J, q is the specific heat of combustion in J/kg, m is the mass of the substance in kg.

For all types of fuel and most combustible substances, the values of the specific heat of combustion have long been determined and tabulated, which are used by specialists when calculating the heat released during the combustion of fuel or other materials. In different tables, slight discrepancies are possible, obviously explained by slightly different measurement methods or different calorific value of the same type of combustible materials extracted from different deposits.

Specific heat of combustion of some types of fuel

Of the solid fuels, coal has the highest energy intensity - 27 MJ / kg (anthracite - 28 MJ / kg). Charcoal has similar indicators (27 MJ / kg). Brown coal is much less calorific - 13 MJ/kg. In addition, it usually contains a lot of moisture (up to 60%), which, evaporating, reduces the value of the total calorific value.

Peat burns with a heat of 14-17 MJ/kg (depending on its condition - crumb, pressed, briquette). Firewood dried to 20% moisture emits from 8 to 15 MJ/kg. At the same time, the amount of energy received from aspen and from birch can almost double. Approximately the same indicators are given by pellets from different materials - from 14 to 18 MJ / kg.

Much less than solid fuels, liquid fuels differ in specific heat of combustion. Thus, the specific heat of combustion of diesel fuel is 43 MJ / l, gasoline - 44 MJ / l, kerosene - 43.5 MJ / l, fuel oil - 40.6 MJ / l.

The specific heat of combustion of natural gas is 33.5 MJ/m³, propane - 45 MJ/m³. The most energy-intensive gaseous fuel is hydrogen gas (120 MJ/m³). It is very promising for use as a fuel, but has not yet been found. best options its storage and transportation.

Comparison of the energy intensity of different types of fuel

When comparing the energy value of the main types of solid, liquid and gaseous fuels, it can be established that one liter of gasoline or diesel fuel corresponds to 1.3 m³ of natural gas, one kilogram hard coal- 0.8 m³ of gas, one kg of firewood - 0.4 m³ of gas.

The heat of combustion of fuel is the most important indicator efficiency, however, the breadth of its distribution in the areas of human activity depends on the technical capabilities and economic indicators of use.

Calorific value of natural gas kcal m3

Information

Login form

Articles about VO

Physical quantities

The heat output of heating equipment is usually presented in kilowatts (kW), kilocalories per hour (kcal/ h) or in megajoules per hour (MJ/ h) .

1 kW = 0.86 kcal/h = 3.6 MJ/h

Energy consumption is measured in kilowatt-hours (kWh), kilocalories (kcal) or megajoules (MJ).

1 kWh = 0.86 kcal = 3.6 MJ

Most domestic heating appliances have a capacity of

within 10 - 45 kW.

Natural gas

Natural gas consumption is usually measured in cubic meters (m3 ) . This value is recorded by your gas meter and it is the gas worker who records it when he takes readings. One cubic meter of natural gas contains 37.5 MJ or 8,958 kcal of energy.

Propane (liquefied gas, LPG)*

Propane consumption is usually measured in liters (l) . One liter of propane contains 25.3 MJ or 6,044 kcal of energy. Basically, all the rules and concepts that apply to natural gas apply to propane, with a slight adjustment for calorie content. Propane has a lower hydrogen content than natural gas. When propane is burned, the amount of heat released in latent form is about 3% less than that of natural gas. This suggests that traditional propane fuel pumps are slightly more productive than those fueled by natural gas. On the other hand, when we are dealing with high-efficiency condensing heaters, the reduced hydrogen content complicates the condensation process and propane heaters are slightly inferior to those that run on natural gas.

* Unlike Canada, not pure propane is common in Ukraine, and propane - butane mixtures, in which the proportion of propane can vary from 20 before 80 %. Butane has a calorie content 6 742 kcal/ l. Important to remember, that the boiling point of propane is minus 43 ° c, and the boiling point of butane – only minus 0,5 ° C. In practice, this leads to, that with a high content of butane in a gas cylinder in the cold, the gas from the cylinder does not evaporate without additional heating .

darnik_truda

Notes of a Traveling Locksmith - Malaga Truth

How much gas is in the bottle

Oxygen, argon, helium, welding mixtures: 40 liters cylinder at 150 atm - 6 cubic meters

Acetylene: 40 liters cylinder at 19 atm - 4.5 cubic meters

Carbon dioxide: 40 liters cylinder - 24 kg - 12 cubic meters

Propane: 50 liters cylinder - 42 liters of liquid gas - 21 kg - 10 cubic meters.

The pressure of oxygen in the cylinder depending on the temperature

40С - 105 atm

-20C - 120 atm

0С - 135 atm

+20С – 150 atm (nominal)

+40C - 165 atm

Welding wire Sv-08 and its derivatives, weight 1 kilometer in length

0.6 - 2.222 kg

0.8 - 3.950 kg

1.0 - 6.173 kg

1.2 - 8.888 kg

Calorific value (calorific value) of liquefied and natural gas

Natural gas – 8500 kcal/m3

Liquefied gas - 21800 kcal / m3

Examples of using the above data

Question: How long will gas and wire last when welding with a semiautomatic device with a 0.8 mm wire cassette weighing 5 kg and a 10 liter carbon dioxide cylinder?

Answer: Welding wire SV-08 with a diameter of 0.8 mm weighs 3.950 kg 1 kilometer, which means that there are about 1200 meters of wire on a 5 kg cassette. If the average feed rate for such a wire is 4 meters per minute, then the cassette will go in 300 minutes. Carbon dioxide in a “large” 40-liter cylinder is 12 cubic meters or 12,000 liters, if converted to a “small” 10-liter cylinder, then there will be 3 cubic meters of carbon dioxide in it. meters or 3000 liters. If the gas flow rate for purge is 10 liters per minute, then a 10-liter cylinder should last 300 minutes or for 1 0.8 wire cassette weighing 5 kg, or a “large” 40 liter cylinder for 4 5 kg cassettes.

Question: I want to put a gas boiler in the country and be heated from cylinders, how long will one cylinder last?

Answer: In a 50-liter “large” propane tank, there are 21 kg of liquefied gas or 10 cubic meters of gas in gaseous form. We find the boiler data, for example, take the very common AOGV-11.6 boiler with a capacity of 11.6 kW and designed for heating 110 square meters. meters. On the ZhMZ website, the consumption is immediately indicated in kilograms per hour for liquefied gas - 0.86 kg per hour when working on full power. We divide 21 kg of gas in a cylinder by 0.86 kg / hour = 18 hours of continuous burning of such a boiler on 1 cylinder, in reality this will happen if it is -30C outside with a standard house and the usual requirement for air temperature in it, and if it is outside will be only -20C, then 1 cylinder will be enough for 24 hours (day). We can conclude that in order to heat an ordinary house of 110 square meters. meters of bottled gas in the cold months of the year, you need about 30 bottles per month. It must be remembered that due to the different calorific value of liquefied and natural gas, the consumption of liquefied and natural gas at the same power for boilers is different. To switch from one type of gas to another in boilers, it is usually necessary to change jets / nozzles. When making calculations, be sure to take this into account and take the flow data specifically for a boiler with jets for the correct gas.

Calorific value of natural gas kcal m3

How much gas is in the cylinder Oxygen, argon, helium, welding mixtures: 40 liters cylinder at 150 atm - 6 cubic meters Acetylene: 40 liters cylinder at 19 atm - 4.5 cubic meters Carbon dioxide: 40 liters cylinder - 24 kg - 12 cubic meters .m Propane: 50 liters cylinder - 42 liters of liquid gas - 21 kg - 10 cubic meters. The oxygen pressure in the cylinder...

Quick reference guide for the beginner welder

How much gas is in the bottle

Oxygen, argon, nitrogen, helium, welding mixtures: 40-liter cylinder at 150 atm - 6 cu. m / helium 1 kg, other compressed gases 8-10 kg

Acetylene: 40-liter cylinder at 19 kgf / cm2 - 4.5 cu. m / 5.5 kg of dissolved gas

Carbonic acid: 40-liter bottle - 12 cu. m / 24 kg liquid gas

Propane: 50 liter tank - 10 cu. m / 42 liters liquid gas / 21 kg liquid gas

How much do balloons weigh

Oxygen, argon, nitrogen, helium, carbon dioxide, welding mixtures: the weight of an empty 40-liter cylinder is 70 kg

Acetylene: weight of an empty 40-liter cylinder - 90 kg

Propane: weight of an empty 50-liter cylinder - 22 kg

What is the thread on the cylinders

Thread for valves in cylinder necks according to GOST 9909-81

W19.2 - 10-liter and smaller cylinders for any gases, as well as carbon dioxide fire extinguishers

W27.8 - 40 liters of oxygen, carbon dioxide, argon, helium, as well as 5, 12, 27 and 50 liters of propane

W30.3 - 40 liter acetylene

M18x1.5 - fire extinguishers (Attention! Do not try to fill carbon dioxide or any compressed gas into powder fire extinguishers, but propane is quite possible.)

Thread on the valve for connecting the reducer

G1 / 2 ″ - often found on 10-liter cylinders, an adapter is needed for a standard gearbox

G3/4″ - standard for 40-liter oxygen, carbon dioxide, argon, helium, welding mixtures

SP 21.8×1/14″ – for propane, left thread

Pressure of oxygen or argon in a fully charged cylinder depending on temperature

40C - 105 kgf/cm2

-20C - 120 kgf/cm2

0C - 135 kgf/cm2

+20C - 150 kgf/cm2 (nominal)

+40C - 165 kgf/cm2

Helium pressure in a fully filled cylinder as a function of temperature

40C - 120 kgf/cm2

-20C - 130 kgf/cm2

0C - 140 kgf/cm2

+20C - 150 kgf/cm2 (nominal)

+40C - 160 kgf/cm2

The pressure of acetylene in a fully filled cylinder depending on the temperature

5C - 13.4 kgf/cm2

0C - 14.0 kgf/cm2

+20C - 19.0 kgf/cm2 (nominal)

+30C - 23.5 kgf/cm2

+40C - 30.0 kgf/cm2

Welding wire Sv-08, weight of 1 kilometer of wire along the length, depending on the diameter

0.6 mm - 2.222 kg

0.8 mm - 3.950 kg

1.0 mm - 6.173 kg

1.2 mm - 8.888 kg

Calorific value (calorific value) of natural and liquefied gas

Natural gas - 8570 kcal/m3

Propane - 22260 kcal/m3

Butane - 29415 kcal/m3

Liquefied gas SUG (average propane-butane mixture) - 25800 kcal/m3

In terms of calorific value, 1 cubic meter of liquefied gas = 3 cubic meters of natural gas!

Differences between household propane cylinders and industrial ones

Household gearboxes for gas stoves such as RDSG-1-1.2 "Frog" and RDSG-2-1.2 "Baltika" - capacity 1.2 m3 / h, outlet pressure 2000 - 3600 Pa (0.02 - 0.036 kgf/cm2).

Industrial gearboxes for flame treatment type BPO-5 - capacity 5 m3/hour, outlet pressure 1 - 3 kgf/cm2.

Basic information about gas welding torches

Torches type G2 "Baby", "Asterisk" are the most common and versatile welding torches, and when buying a torch for general purposes, it is worth purchasing them. Burners can be equipped with different tips, and depending on the installed tip, have different characteristics:

Tip No. 1 - thickness of the welded metal 0.5 - 1.5 mm - average consumption of acetylene / oxygen 75/90 l / h

Tip No. 2 - thickness of the welded metal 1 - 3 mm - average consumption of acetylene / oxygen 150/180 l / h

Tip No. 3 - thickness of the welded metal 2 - 4 mm - average consumption of acetylene / oxygen 260/300 l / h

It is important to know and remember that acetylene torches cannot work stably on propane, and for welding, soldering, heating parts with a propane-oxygen flame, it is necessary to use GZU type burners and others specially designed to work on propane-butane. It must be taken into account that welding with a propane-oxygen flame gives worst performance seam than welding with acetylene or electric welding, and therefore should be resorted to only in exceptional cases, but soldering or heating with propane can be even more comfortable than with acetylene. The characteristics of propane-oxygen burners, depending on the installed tip, are as follows:

Tip No. 1 - average consumption of propane-butane / oxygen 50/175 l / h

Tip No. 2 - average consumption of propane-butane / oxygen 100/350 l / h

Tip No. 3 - average consumption of propane-butane / oxygen 200/700 l / h

For the correct and safe operation of the burner, it is very important to set the correct gas pressure at the inlet to it. All modern burners are injector, i.e. combustible gas is sucked into them by an oxygen jet passing through the central channel of the injector, and therefore the oxygen pressure must be higher than the pressure of the combustible gas. Usually set the following pressure:

Oxygen pressure at the burner inlet - 3 kgf/cm2

The pressure of acetylene or propane at the inlet to the burner is 1 kgf / cm2

Injection burners are the most resistant to backfire and are recommended for use. In older, non-injector torches, the pressure of oxygen and combustible gas is set equal, whereby the development of backfire is facilitated, this makes such a torch more dangerous, especially for beginner gas welders who often manage to dip the torch mouthpiece into the weld pool, which is extremely dangerous.

Also, always follow the correct sequence of opening / closing the burner valves when igniting / extinguishing it. When ignited, oxygen is always opened first, then combustible gas. When extinguishing, the combustible gas is closed first, and then oxygen. Please note that when the burner is turned off in this sequence, popping may occur - do not be afraid, this is normal.

Be sure to correctly set the ratio of gases in the flame of the burner. With the correct ratio of combustible gas and oxygen, the core of the flame (a small bright luminous area right at the mouthpiece) is fat, thick, clearly defined, does not have a veil in the flame of the torch around. With an excess of combustible gas, there will be a veil around the core. With an excess of oxygen, the nucleus will become pale, sharp, prickly. To correctly set the composition of the flame, first give an excess of combustible gas so that a veil appears around the core, and then gradually add oxygen or remove combustible gas until the veil completely disappears, and immediately stop turning the valves, this will be the optimal welding flame. Welding should be carried out with a flame zone at the very tip of the core, but in no case should the core itself be stuck into the weld pool, and not carried too far.

Do not confuse a welding torch and a gas cutter. Welding torches have two valves, and a cutting torch has three valves. Two gas cutter valves are responsible for the preheating flame, and the third additional valve opens a jet of cutting oxygen, which, passing through the central channel of the mouthpiece, causes the metal to burn in the cut zone. It is important to understand that a gas cutter cuts not by melting metal from the cut zone, but by burning it out, followed by removal of slag by the dynamic action of a jet of cutting oxygen. In order to cut metal with a gas cutter, it is necessary to light a preheating flame, acting in the same way as in the case of ignition of a welding torch, bring the cutter to the edge of the cut, heat a small local area of metal to a red glow and abruptly open the cutting oxygen valve. After the metal catches fire and a cut begins to form, the cutter begins to move in accordance with the required cut path. At the end of the cut, the cutting oxygen valve must be closed, leaving only the preheating flame. The cut should always start only from the edge, but if there is an urgent need to start the cut not from the edge, but from the middle, then you should not “pierce” the metal with a cutter, it is better to drill a through hole and start cutting from it, it is much safer. Some acrobatic welders manage to cut thin metal with conventional welding torches by deftly manipulating the fuel gas valve, periodically shutting it off and leaving pure oxygen, and then re-igniting the torch on hot metal, and although this can be seen quite often, it is worth warning that you do this dangerous, and the cut quality is poor.

How many cylinders can be transported without special permits

Rules for the transport of gases by car are regulated by the Regulations for the Transport of Dangerous Goods by Road (POGAT), which in turn are consistent with the requirements of the European Agreement concerning the International Carriage of Dangerous Goods (ADR).

Paragraph POGAT 1.2 states that “The Rules do not apply to. transportation of a limited number of hazardous substances in one vehicle, the carriage of which can be considered as the carriage of non-dangerous goods. The limited quantity of dangerous goods is defined in the requirements for safe transportation particular type of dangerous goods. When determining it, it is possible to use the requirements of the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR)”.

According to ADR, all gases belong to the second class of hazardous substances, while different gases may have different dangerous properties: A - asphyxiating gases, O - oxidizing substances, F - flammable substances. Asphyxiating and oxidizing gases belong to the third transport category, and flammable - to the second. The maximum amount of dangerous goods, the carriage of which is not subject to the Rules, is indicated in ADR clause 1.1.3.6, and is 1000 units for the third transport category (classes 2A and 2O), and for the second transport category (class 2F) the maximum amount is 333 units . For gases, one unit is understood as 1 liter of vessel capacity, or 1 kg of liquefied or dissolved gas.

Thus, according to POGAT and ADR, the following number of cylinders can be freely transported by car: oxygen, argon, nitrogen, helium and welding mixtures - 24 cylinders of 40 liters each; carbon dioxide - 41 cylinders of 40 liters; propane - 15 cylinders of 50 liters, acetylene - 18 cylinders of 40 liters. (Note: acetylene is stored in cylinders dissolved in acetone, and each cylinder, in addition to gas, contains 12.5 kg of the same combustible acetone, which is taken into account in the calculations.)

When transporting different gases together, ADR clause 1.1.3.6.4 should be followed: “If dangerous goods belonging to different transport categories are transported in the same transport unit, the sum of the quantities of substances and articles of transport category 2, multiplied by “3”, and the quantity of substances and articles of transport category 3 shall not exceed 1000 units”.

Also, ADR clause 1.1.3.1 contains an indication that: “The provisions of ADR do not apply. to the carriage of dangerous goods by private persons when these goods are packaged for retail and are intended for their personal consumption, domestic use, leisure or sport, provided that steps are taken to prevent any leakage of the contents under normal conditions of carriage.”

Additionally, there is an explanation of the DOBDD of the Ministry of Internal Affairs of Russia dated July 26, 2006, ref. 13/2-121, according to which “Transportation of compressed argon, dissolved acetylene, compressed oxygen and propane in cylinders of 50 liters. without complying with the requirements of the Rules for the carriage of dangerous goods by road, it is possible to carry out on one transport unit in the following quantities: dissolved acetylene or propane - no more than 6 cylinders, argon or compressed oxygen - no more than 20 cylinders. In the case of the joint transportation of two of the indicated dangerous goods, the following ratios by the number of cylinders are possible: 1 cylinder with acetylene and 17 cylinders with oxygen or argon; 2 and 14; 3 and 11; 4 and 8; 5 and 5; 6 and 2. The same ratios are possible in the case of transportation of propane and compressed oxygen or argon. When transporting compressed argon and oxygen together, the maximum number should not exceed 20 cylinders, regardless of their ratio, and when transporting acetylene and propane together, 6 cylinders, also regardless of their ratio.”

Based on the foregoing, it is recommended to be guided by the instructions of the DOBDD of the Ministry of Internal Affairs of Russia dated July 26, 2006, ref. 13 / 2-121, the least is allowed there and the amount is directly indicated, what is possible and how. In this instruction, of course, they forgot about carbon dioxide, but you can always say that it is equal to argon, traffic police officers, as a rule, are not great chemists and this is enough for them. Remember that POGAT / ADR is completely on your side here, carbon dioxide can be transported through them even more than argon. The truth will be yours anyway. As of 2014, the author is aware of at least 4 lawsuits won against the traffic police, when people were tried to be punished for transporting fewer cylinders than fall under the POGAT / ADR.

Examples of using the above data in practice and in calculations

Question: How long will gas and wire last when welding with a semiautomatic device with a 0.8 mm wire cassette weighing 5 kg and a 10 liter carbon dioxide cylinder?

Answer: Welding wire SV-08 with a diameter of 0.8 mm weighs 3.950 kg 1 kilometer, which means that there are approximately 1200 meters of wire on a 5 kg cassette. If the average feed rate for such a wire is 4 meters per minute, then the cassette will go in 300 minutes. Carbon dioxide in a “large” 40-liter cylinder is 12 cubic meters or 12,000 liters, if converted to a “small” 10-liter cylinder, then there will be 3 cubic meters of carbon dioxide in it. meters or 3000 liters. If the gas flow rate for purge is 10 liters per minute, then a 10-liter cylinder should last 300 minutes or for 1 0.8 wire cassette weighing 5 kg, or a “large” 40 liter cylinder for 4 5 kg cassettes.

Question: I want to put a gas boiler in the country and be heated from cylinders, how long will one cylinder last?

Answer: In a 50-liter “large” propane cylinder, there are 21 kg of liquefied gas or 10 cubic meters of gas in gaseous form, but it’s impossible to convert it directly into cubic meters and calculate the consumption from them, because the calorific value of liquefied propane-butane is 3 times higher than the calorific value of natural gas, and the consumption of natural gas is usually written on boilers! It’s more correct to do this: we find the boiler data immediately for liquefied gas, for example, take the very common AOGV-11.6 boiler with a capacity of 11.6 kW and designed for heating 110 square meters. meters. On the ZhMZ website, the consumption is immediately indicated in kilograms per hour for liquefied gas - 0.86 kg per hour when operating at full capacity. We divide 21 kg of gas in a cylinder by 0.86 kg / hour = 18 hours of continuous burning of such a boiler on 1 cylinder, in reality this will happen if it is -30C outside with a standard house and the usual requirement for air temperature in it, and if it is outside will be only -20C, then 1 cylinder will be enough for 24 hours (day). We can conclude that in order to heat an ordinary house of 110 square meters. meters of bottled gas in the cold months of the year, you need about 30 bottles per month. It must be remembered that due to the different calorific value of liquefied and natural gas, the consumption of liquefied and natural gas at the same power for boilers is different. To switch from one type of gas to another in boilers, it is usually necessary to change jets / nozzles. And now, for those who are interested, you can also calculate through cubes. On the same website of ZhMZ, the consumption of the AOGV-11.6 boiler for natural gas is also given, it is 1.3 cubic meters per hour, i.e. 1.3 cubic meters of natural gas per hour are equal to the consumption of liquefied gas 0.86 kg / hour. In gaseous form, 0.86 kg of liquefied propane-butane is approximately equal to 0.43 cubic meters of gaseous propane-butane. Remember that propane-butane is three times more “powerful” than natural gas. We check: 0.43 x 3 \u003d 1.26 cubes. Bingo!

Question: I bought a burner of the GV-1 type (GVN-1, GVM-1), connected it to the cylinder through the RDSG-1 “Frog”, but it barely burns. Why?

Answer: For the operation of gas-air propane burners used for flame treatment, a gas pressure of 1–3 kgf/cm2 is required, and a household gearbox designed for gas stoves produces 0.02–0.036 kg/cm2, which is clearly not enough. Also, household propane reducers are not designed for large throughput to work with powerful industrial burners. In your case, you need to use a gearbox type BPO-5.

Question: I bought a gas heater for the garage, found a propane reducer from a BPO-5 gas cutter, connected the heater through it. The heater blazes with fire and burns unsteadily. What to do?

Answer: Household gas appliances are usually designed for a gas pressure of 0.02 - 0.036 kg / cm2, this is how much a household reducer of the RDSG-1 “Frog” type produces, and industrial cylinder reducers are designed for a pressure of 1 - 3 kgf / cm2, which is at least 50 times more . Naturally, when such excess pressure is blown into a household gas appliance, it cannot work correctly. You need to study the instructions for your gas appliance and use the correct reducer that produces exactly the gas pressure at the inlet to the appliance that it requires.

Question: How much acetylene and oxygen is enough when welding pipes in plumbing work?

Answer: A 40 liter bottle contains 6 cu. m of oxygen or 4.5 cubic meters. m of acetylene. The average gas consumption of a G2 type burner with a No. 3 nozzle installed, most often used for plumbing work, is 260 liters of acetylene and 300 liters of oxygen per hour. So oxygen is enough for: 6 cubic meters. m = 6000 liters / 300 l / h = 20 hours, and acetylene: 4500 liters / 260 l / h = 17 hours. Total: a pair of fully charged 40-liter acetylene + oxygen cylinders is approximately enough for 17 hours of continuous burning of the burner, which in practice is usually 3 shifts of the welder's work for 8 hours each.

Question: Is it necessary or not, according to POGAT / ADR, to issue special permits for the transportation of 2 propane cylinders and 4 oxygen cylinders in one car?

Answer: According to ADR clause 1.1.3.6.4, we calculate: 21 (weight of liquid propane in each cylinder) * 2 (number of propane cylinders) * 3 (coefficient from ADR clause 1.1.3.6.4) + 40 (volume of oxygen in the cylinder in liters, compressed oxygen in the cylinder) * 4 (number of oxygen cylinders) = 286 units. The result is less than 1000 units, such a number of cylinders and in such a combination can be transported freely, without issuing special documents. In addition, there is an explanation of the DOBDD of the Ministry of Internal Affairs of Russia dated July 26, 2006, ref. 13/2-121, expressly indicating that such transportation is allowed to be carried out without complying with the requirements of the POGAT.

Quick reference guide for the beginner welder

Quick reference guide for a beginner welder How much gas is in a cylinder Oxygen, argon, nitrogen, helium, welding mixtures: 40-liter cylinder at 150 atm - 6 cubic meters. m / helium 1 kg, other compressed gases 8-10 kg

(Fig. 14.1 - Calorific value

fuel capacity)

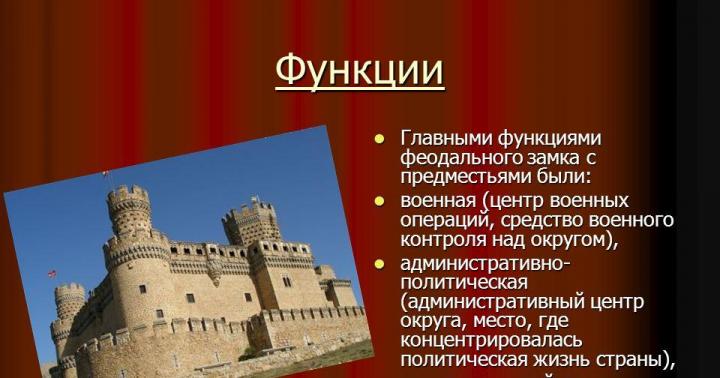

Pay attention to the calorific value (specific heat of combustion) various kinds fuel, compare performance. The calorific value of the fuel characterizes the amount of heat released during the complete combustion of fuel with a mass of 1 kg or a volume of 1 m³ (1 l). The most common calorific value is measured in J/kg (J/m³; J/L). The higher the specific heat of combustion of fuel, the lower its consumption. Therefore, the calorific value is one of the most significant characteristics of the fuel.

The specific heat of combustion of each type of fuel depends on:

- From its combustible components (carbon, hydrogen, volatile combustible sulfur, etc.).

- From its moisture and ash content.

| Table 4 - Specific heat of combustion of various energy carriers, comparative analysis of costs. | |||||||||

| Type of energy carrier | Calorific value | Volumetric matter density (ρ=m/V) | Unit price reference fuel | Coeff. useful action (efficiency) systems heating, % | Price per 1 kWh | Implemented systems | |||

| MJ | kWh | ||||||||

| (1MJ=0.278kWh) | |||||||||

| Electricity | - | 1.0 kWh | - | 3.70 rub. per kWh | 98% | 3.78 rubles | Heating, hot water supply (DHW), air conditioning, cooking | ||

| Methane (CH4, temperature boiling point: -161.6 °C) | 39.8 MJ/m³ | 11.1 kWh/m³ | 0.72 kg/m³ | 5.20 rub. per m³ | 94% | 0.50 rub. | |||

| Propane (C3H8, temperature boiling point: -42.1 °C) | 46,34 MJ/kg | 23,63 MJ/l | 12,88 kWh/kg | 6,57 kWh/l | 0.51 kg/l | 18.00 rub. Hall | 94% | 2.91 rub. | Heating, hot water supply (DHW), cooking, backup and permanent power supply, autonomous septic tank (sewerage), outdoor infrared heaters, outdoor barbecues, fireplaces, saunas, designer lighting |

| Butane C4H10, temperature boiling point: -0.5 °C) | 47,20 MJ/kg | 27,38 MJ/l | 13,12 kWh/kg | 7,61 kWh/l | 0.58 kg/l | 14.00 rub. Hall | 94% | 1.96 rub. | Heating, hot water supply (DHW), cooking, backup and permanent power supply, autonomous septic tank (sewerage), outdoor infrared heaters, outdoor barbecues, fireplaces, saunas, designer lighting |

| propane butane (LPG - liquefied hydrocarbon gas) | 46,8 MJ/kg | 25,3 MJ/l | 13,0 kWh/kg | 7,0 kWh/l | 0.54 kg/l | 16.00 rub. Hall | 94% | 2.42 rubles | Heating, hot water supply (DHW), cooking, backup and permanent power supply, autonomous septic tank (sewerage), outdoor infrared heaters, outdoor barbecues, fireplaces, saunas, designer lighting |

| Diesel fuel | 42,7 MJ/kg | 11,9 kWh/kg | 0.85 kg/l | 30.00 rub. per kg | 92% | 2.75 rub. | Heating (heating water and generating electricity are very costly) | ||

| Firewood (birch, humidity - 12%) | 15,0 MJ/kg | 4,2 kWh/kg | 0.47-0.72 kg/dm³ | 3.00 rub. per kg | 90% | 0.80 rub. | Heating (inconvenient to cook food, almost impossible to get hot water) | ||

| Coal | 22,0 MJ/kg | 6,1 kWh/kg | 1200-1500 kg/m³ | 7.70 rub. per kg | 90% | 1.40 rub. | Heating | ||

| MAPP gas (mixture of liquefied petroleum gas - 56% with methyl acetylene-propadiene - 44%) | 89,6 MJ/kg | 24,9 kWh/m³ | 0.1137 kg/dm³ | -R. per m³ | 0% | Heating, hot water supply (DHW), cooking, backup and permanent power supply, autonomous septic tank (sewerage), outdoor infrared heaters, outdoor barbecues, fireplaces, saunas, designer lighting | |||

(Fig. 14.2 - Specific heat of combustion)

According to the table “Specific calorific value of various energy carriers, comparative analysis of costs”, propane-butane (liquefied hydrocarbon gas) is inferior in economic benefits and prospects of using only natural gas (methane). However, attention should be paid to the trend towards an inevitable increase in the cost of main gas, which today is significantly underestimated. Analysts predict an inevitable reorganization of the industry, which will lead to a significant rise in the price of natural gas, perhaps even exceed the cost of diesel fuel.

Thus, liquefied hydrocarbon gas, the cost of which will remain practically unchanged, remains extremely promising - the optimal solution for autonomous gasification systems.

The tables present the mass specific heat of combustion of fuel (liquid, solid and gaseous) and some other combustible materials. Fuels such as: coal, firewood, coke, peat, kerosene, oil, alcohol, gasoline, natural gas, etc. are considered.

List of tables:

In an exothermic fuel oxidation reaction, its chemical energy is converted into thermal energy with the release of a certain amount of heat. The resulting thermal energy is called the heat of combustion of the fuel. It depends on its chemical composition, humidity and is the main one. The calorific value of fuel, referred to 1 kg of mass or 1 m 3 of volume, forms the mass or volumetric specific calorific value.

The specific heat of combustion of fuel is the amount of heat released during the complete combustion of a unit mass or volume of solid, liquid or gaseous fuel. AT international system units, this value is measured in J / kg or J / m 3.

The specific heat of combustion of a fuel can be determined experimentally or calculated analytically. Experimental methods for determining the calorific value are based on the practical measurement of the amount of heat released during the combustion of fuel, for example, in a calorimeter with a thermostat and a combustion bomb. For a fuel with a known chemical composition, the specific heat of combustion can be determined from Mendeleev's formula.

There are higher and lower specific heats of combustion. The gross calorific value is equal to the maximum amount of heat released during complete combustion of the fuel, taking into account the heat spent on the evaporation of the moisture contained in the fuel. The lower calorific value is less than the higher value by the value of the heat of condensation, which is formed from the moisture of the fuel and the hydrogen of the organic mass, which turns into water during combustion.

To determine fuel quality indicators, as well as in heat engineering calculations usually use the lowest specific heat of combustion, which is the most important thermal and operational characteristic of the fuel and is given in the tables below.

Specific heat of combustion of solid fuel (coal, firewood, peat, coke)

The table shows the values of the specific heat of combustion of dry solid fuel in the unit of MJ/kg. The fuel in the table is arranged by name in alphabetical order.

Of the considered solid fuels, coking coal has the highest calorific value - its specific heat of combustion is 36.3 MJ/kg (or 36.3·10 6 J/kg in SI units). In addition, high calorific value is characteristic of coal, anthracite, charcoal and brown coal.

Fuels with low energy efficiency include wood, firewood, gunpowder, freztorf, oil shale. For example, the specific heat of combustion of firewood is 8.4 ... 12.5, and gunpowder - only 3.8 MJ / kg.

| Fuel | |

|---|---|

| Anthracite | 26,8…34,8 |

| Wood pellets (pillets) | 18,5 |

| Firewood dry | 8,4…11 |

| Dry birch firewood | 12,5 |

| gas coke | 26,9 |

| blast-furnace coke | 30,4 |

| semi-coke | 27,3 |

| Powder | 3,8 |

| Slate | 4,6…9 |

| Oil shale | 5,9…15 |

| Solid propellant | 4,2…10,5 |

| Peat | 16,3 |

| fibrous peat | 21,8 |

| Milling peat | 8,1…10,5 |

| Peat crumb | 10,8 |

| Brown coal | 13…25 |

| Brown coal (briquettes) | 20,2 |

| Brown coal (dust) | 25 |

| Donetsk coal | 19,7…24 |

| Charcoal | 31,5…34,4 |

| Coal | 27 |

| Coking coal | 36,3 |

| Kuznetsk coal | 22,8…25,1 |

| Chelyabinsk coal | 12,8 |

| Ekibastuz coal | 16,7 |

| freztorf | 8,1 |

| Slag | 27,5 |

Specific heat of combustion of liquid fuel (alcohol, gasoline, kerosene, oil)

The table of specific heat of combustion of liquid fuel and some other organic liquids is given. It should be noted that fuels such as gasoline, diesel fuel and oil are characterized by high heat release during combustion.

The specific heat of combustion of alcohol and acetone is significantly lower than traditional motor fuels. In addition, liquid rocket fuel has a relatively low calorific value and, with the complete combustion of 1 kg of these hydrocarbons, an amount of heat equal to 9.2 and 13.3 MJ, respectively, will be released.

| Fuel | Specific heat of combustion, MJ/kg |

|---|---|

| Acetone | 31,4 |

| Gasoline A-72 (GOST 2084-67) | 44,2 |

| Aviation gasoline B-70 (GOST 1012-72) | 44,1 |

| Gasoline AI-93 (GOST 2084-67) | 43,6 |

| Benzene | 40,6 |

| Winter diesel fuel (GOST 305-73) | 43,6 |

| Summer diesel fuel (GOST 305-73) | 43,4 |

| Liquid propellant (kerosene + liquid oxygen) | 9,2 |

| Aviation kerosene | 42,9 |

| Lighting kerosene (GOST 4753-68) | 43,7 |

| xylene | 43,2 |

| High sulfur fuel oil | 39 |

| Low-sulfur fuel oil | 40,5 |

| Low sulfur fuel oil | 41,7 |

| Sulphurous fuel oil | 39,6 |

| Methyl alcohol (methanol) | 21,1 |

| n-Butyl alcohol | 36,8 |

| Oil | 43,5…46 |

| Oil methane | 21,5 |

| Toluene | 40,9 |

| White spirit (GOST 313452) | 44 |

| ethylene glycol | 13,3 |

| Ethyl alcohol (ethanol) | 30,6 |

Specific heat of combustion of gaseous fuel and combustible gases

A table of the specific heat of combustion of gaseous fuel and some other combustible gases in the dimension of MJ/kg is presented. Of the considered gases, the largest mass specific heat of combustion differs. With the complete combustion of one kilogram of this gas, 119.83 MJ of heat will be released. Also, a fuel such as natural gas has a high calorific value - the specific heat of combustion of natural gas is 41 ... 49 MJ / kg (for pure 50 MJ / kg).

| Fuel | Specific heat of combustion, MJ/kg |

|---|---|

| 1-Butene | 45,3 |

| Ammonia | 18,6 |

| Acetylene | 48,3 |

| Hydrogen | 119,83 |

| Hydrogen, mixture with methane (50% H 2 and 50% CH 4 by mass) | 85 |

| Hydrogen, mixture with methane and carbon monoxide (33-33-33% by weight) | 60 |

| Hydrogen, mixture with carbon monoxide (50% H 2 50% CO 2 by mass) | 65 |

| Blast Furnace Gas | 3 |

| coke oven gas | 38,5 |

| LPG liquefied hydrocarbon gas (propane-butane) | 43,8 |

| Isobutane | 45,6 |

| Methane | 50 |

| n-butane | 45,7 |

| n-Hexane | 45,1 |

| n-Pentane | 45,4 |

| Associated gas | 40,6…43 |

| Natural gas | 41…49 |

| Propadien | 46,3 |

| Propane | 46,3 |

| Propylene | 45,8 |

| Propylene, mixture with hydrogen and carbon monoxide (90%-9%-1% by weight) | 52 |

| Ethane | 47,5 |

| Ethylene | 47,2 |

Specific heat of combustion of some combustible materials

A table is given of the specific heat of combustion of some combustible materials (, wood, paper, plastic, straw, rubber, etc.). It should be noted materials with high heat release during combustion. Such materials include: rubber of various types, expanded polystyrene (polystyrene), polypropylene and polyethylene.

| Fuel | Specific heat of combustion, MJ/kg |

|---|---|

| Paper | 17,6 |

| Leatherette | 21,5 |

| Wood (bars with a moisture content of 14%) | 13,8 |

| Wood in stacks | 16,6 |

| Oak wood | 19,9 |

| Spruce wood | 20,3 |

| wood green | 6,3 |

| Pine wood | 20,9 |

| Kapron | 31,1 |

| Carbolite products | 26,9 |

| Cardboard | 16,5 |

| Styrene-butadiene rubber SKS-30AR | 43,9 |

| Natural rubber | 44,8 |

| Synthetic rubber | 40,2 |

| Rubber SCS | 43,9 |

| Chloroprene rubber | 28 |

| Polyvinyl chloride linoleum | 14,3 |

| Two-layer polyvinyl chloride linoleum | 17,9 |

| Linoleum polyvinylchloride on a felt basis | 16,6 |

| Linoleum polyvinyl chloride on a warm basis | 17,6 |

| Linoleum polyvinylchloride on a fabric basis | 20,3 |

| Linoleum rubber (relin) | 27,2 |

| Paraffin solid | 11,2 |

| Polyfoam PVC-1 | 19,5 |

| Polyfoam FS-7 | 24,4 |

| Polyfoam FF | 31,4 |

| Expanded polystyrene PSB-S | 41,6 |

| polyurethane foam | 24,3 |

| fibreboard | 20,9 |

| Polyvinyl chloride (PVC) | 20,7 |

| Polycarbonate | 31 |

| Polypropylene | 45,7 |

| Polystyrene | 39 |

| High density polyethylene | 47 |

| Low-pressure polyethylene | 46,7 |

| Rubber | 33,5 |

| Ruberoid | 29,5 |

| Soot channel | 28,3 |

| Hay | 16,7 |

| Straw | 17 |

| Organic glass (plexiglass) | 27,7 |

| Textolite | 20,9 |

| Tol | 16 |

| TNT | 15 |

| Cotton | 17,5 |

| Cellulose | 16,4 |

| Wool and wool fibers | 23,1 |

Sources:

- GOST 147-2013 Solid mineral fuel. Determination of the higher calorific value and calculation of the lower calorific value.

- GOST 21261-91 Petroleum products. Method for determining the gross calorific value and calculating the net calorific value.

- GOST 22667-82 Combustible natural gases. Calculation method determination of heat of combustion, relative density and Wobbe number.

- GOST 31369-2008 Natural gas. Calculation of calorific value, density, relative density and Wobbe number based on component composition.

- Zemsky G. T. Flammable properties of inorganic and organic materials: reference book M.: VNIIPO, 2016 - 970 p.

Length and Distance Converter Mass Converter Bulk Food and Food Volume Converter Area Converter Volume and Cooking Recipe Converter Temperature Converter Pressure Converter mechanical stress, Young's Modulus Energy and Work Converter Power Converter Force Converter Time Converter Linear Velocity Converter Flat Angle Thermal Efficiency and Fuel Economy Converter Number to various systems calculus Converter of units of measurement of the amount of information Exchange rates Sizes women's clothing and footwear Sizes of men's clothing and footwear Angular velocity and rotational speed converter Acceleration converter Angular acceleration converter Density converter Specific volume converter Moment of inertia converter Moment of force converter Torque converter Specific heat of combustion (by mass) Converter of energy density and specific heat of combustion of fuel (by mass) Temperature difference converter Thermal expansion coefficient converter Thermal resistance converter Thermal conductivity converter concentration in solution Dynamic (Absolute) Viscosity Converter Kinematic Viscosity Converter Converter surface tension Vapor Permeability Converter Water Vapor Flux Density Converter Sound Level Converter Microphone Sensitivity Converter Sound Pressure Level (SPL) Converter Sound Pressure Level Converter with Selectable Reference Pressure Brightness Converter Luminous Intensity Converter Illumination Converter Computer Graphics Resolution Converter Frequency and Wavelength Converter Power in Diopters and focal length Diopter Power and Lens Magnification (×) Electric Charge Converter Linear Charge Density Converter Surface Charge Density Converter Volumetric Charge Density Converter Electric Current Converter Linear Current Density Converter Surface Current Density Converter Electric Field Strength Converter Electrostatic Potential and Voltage Converter Electrical Resistance Converter Specific Resistivity Converter Electrical Resistance Electrical Conductivity Converter Electrical Conductivity Converter Capacitance Inductance Converter US Wire Gauge Converter Levels in dBm (dBm or dBm), dBV (dBV), watts, etc. units Magnetomotive Force Converter Magnetic Field Strength Converter Magnetic Flux Converter Magnetic Induction Converter Radiation . Ionizing Radiation Absorbed Dose Rate Converter Radioactivity. Radioactive Decay Converter Radiation. Exposure Dose Converter Radiation. Absorbed Dose Converter Decimal Prefix Converter Data Transfer Typography and Image Processing Unit Converter Timber Volume Unit Converter Periodic system chemical elements D. I. Mendeleev

1 kilojoule per cubic meter [kJ/m³] = 0.2388458966 international kilocalorie per cubic meter meter

Initial value

Converted value

joule per cubic meter joule per liter megajoule per cubic meter kilojoule per cubic meter international kilocalorie per cubic meter meter thermochemical calorie per cu. centimeter therm per cubic foot therm per gallon imp. term. unit (IT) per cu. British pound term. unit (therm.) per cu. pound centigrade heat unit per cu. pound cubic meter per joule liter per joule amer. gallon per horsepower hour gallon per metric hp-hour

Specific heat

Learn more about energy density and specific heating value of fuel (by volume)

The Energy Density and Heat of Combustion (by Volume) Converter is used to convert units of several physical quantities that are used to quantification energy properties of substances in various fields of science and technology.

Definitions and units

Energy Density

Energy Density fuel, also called energy intensity, is defined as the amount of energy released during the complete combustion of fuel, per unit of its mass or volume. Unlike of English language, where there are two terms for energy density in mass and volume, in Russian one term is used - energy density when talking about the energy density in terms of both mass and volume.

Thus, the energy density, specific heat of combustion and energy intensity characterize a substance or a thermodynamic system. The energy density can also characterize a system in which no combustion occurs at all. For example, energy can be stored in a lithium battery or a lithium-ion battery in the form of chemical energy, a supercharger, or even in a conventional transformer in the form of electromagnetic field energy, in which case one can also speak of energy density.

Specific fuel consumption

Specific fuel consumption- this is also an energy characteristic, but no longer of a substance, but of a specific engine in which the fuel burns to convert the chemical energy of the fuel into useful work to move vehicle. Specific consumption is equal to the ratio of fuel consumption per unit time to power(for car engines) or to thrust(for aviation and rocket engines that create traction; this does not include aircraft piston and turboprop engines). In English terminology, two types of specific fuel consumption are clearly distinguished: specific consumption(fuel consumption per unit of time) per unit of power (eng. brake specific fuel consumption) or per unit of thrust (eng. thrust specific fuel consumption). The word "brake" (English brake) indicates that the specific fuel consumption is determined on a dyno, the main element of which is a brake device.

Specific fuel consumption by volume, the units of which can be converted in this converter, is equal to the ratio of the volumetric fuel consumption (for example, liters per hour) to the engine power or, which is the same, the ratio of the volume of fuel spent on the execution certain work. For example, a specific fuel consumption of 100 g/kW∙h means that the engine must consume 100 grams of fuel per hour to create a power of 1 kilowatt or, what is the same, to perform useful work in 1 kilowatt-hour, the engine must use 100 g of fuel.

Units

Bulk energy density measured in units of energy per volume, such as joules per cubic meter (J/m³, SI) or British thermal units per cubic foot (BTU/ft³, British Traditional).

As we understood, the units J/m³, J/l, kcal/m³, BTU/lb³ are used to measure several physical quantities that have much in common. They are used to measure:

- the energy content of the fuel, that is, the energy content of the fuel by volume

- calorific value of fuel per unit volume

- volumetric energy density in a thermodynamic system.

During the redox reaction of fuel with oxygen, a relatively large amount of energy is released. The amount of energy released during combustion is determined by the type of fuel, the conditions of its combustion, and the mass or volume of the combusted fuel. For example, partially oxidized fuels such as ethanol (ethanol C₂H₅OH) are less efficient than hydrocarbon fuels such as kerosene or gasoline. Energy is usually measured in joules (J), calories (cal) or British thermal units (BTU). The energy intensity of a fuel or its heat of combustion is the energy obtained when a certain volume or a certain mass of fuel is burned. The specific heat of combustion of fuel shows the amount of heat that is released during the complete combustion of a unit volume or mass of fuel.

The energy content of a fuel can be expressed as follows:

- in units of energy per mole of fuel, for example, kJ/mol;

- in units of energy per mass of fuel, such as BTU/lb;

- in units of energy per volume of fuel, e.g. kcal/m³.

The same units, physical quantities and even measurement methods (liquid calorimeter-integrator) are used to measure the energy value of food. In this case, the energy value is defined as the amount of heat released during the combustion of a certain amount food product. Note again that this converter is used to convert units of volume, not mass quantities.

Higher and lower calorific value of fuel

The measured calorific value of a fuel depends on what happens to the water during combustion. Recall that a lot of heat is needed to form steam, and that a large amount of heat is released during the transformation of water vapor into a liquid state. If the water remains in a vapor state when the fuel is burned and its characteristics are measured, then it contains heat that will not be measured. Thus, only the net energy contained in the fuel will be measured. They say it measures lower calorific value of fuel. If during measurement (or operation of the engine) the water completely condenses from the vapor state and cools to the initial temperature of the fuel before it starts burning, a significantly larger amount of heat released will be measured. They say that it is measured gross calorific value of fuel. Please note that the engine internal combustion cannot use the additional energy that is released during the condensation of steam. Therefore, it is more correct to measure the net calorific value, which is what many manufacturers do when measuring the fuel consumption of engines. However American manufacturers often indicate data in the characteristics of manufactured engines, taking into account the higher calorific value. The difference between these values for the same engine is approximately 10%. This is not very much, but leads to confusion if in technical specifications engine no measurement method specified.

Note that the higher and lower calorific values refer only to fuels containing hydrogen, such as gasoline or diesel fuel. When burning pure carbon or carbon monoxide, the higher and lower calorific values cannot be determined, since these substances do not contain hydrogen and, therefore, water is not formed during their combustion.

When fuel is burned in an engine, the actual amount of mechanical work performed as a result of fuel combustion depends to a large extent on the engine itself. Gasoline engines are less efficient than diesel engines in this respect. For example, diesel engines cars have an energy efficiency factor of 30–40%, while the same value for gasoline engines is only 20–30%.

Measuring the energy intensity of a fuel

The specific heat of combustion of a fuel is convenient for comparing different types of fuel. In most cases, the energy content of the fuel is determined in a liquid calorimeter-integrator with an isothermal shell, in which the measurement is carried out while maintaining a constant volume in the so-called "calorimetric bomb", that is, a thick-walled pressure vessel. The heat of combustion or energy intensity is defined as the amount of heat that is released in the vessel during the combustion of an accurately weighed mass of a fuel sample in an oxygen environment. The volume of the vessel in which the fuel burns does not change.

In such calorimeters, the pressure vessel in which the sample is burned is filled with pure oxygen under pressure. A little more oxygen is added than is necessary for complete combustion of the sample. The pressure vessel of the calorimeter must be able to withstand the pressure of the gases produced by the combustion of the fuel. When burned, all of the carbon and hydrogen react with oxygen to form carbon dioxide and water. If combustion is not complete, for example, due to lack of oxygen, carbon monoxide (carbon monoxide CO) is formed or the fuel simply does not burn, which leads to incorrect, underestimated results.

The energy released by the combustion of a fuel sample in a pressure vessel is distributed between the pressure vessel and an absorbing medium (usually water) surrounding the pressure vessel. The temperature rise resulting from the reaction is measured. Then the heat of combustion of the fuel is calculated. To do this, the results of temperature measurements and calibration tests are used, for which material with known characteristics is burned in this calorimeter.

Any liquid calorimeter-integrator consists of the following parts:

- a thick-walled high-pressure vessel (“bomb”) in which a chemical combustion reaction takes place (4);

- a liquid calorimeter vessel, usually having highly polished outer walls to reduce heat transfer; in this vessel with water (5) a "bomb" is placed;

- mixer

- a thermally insulated casing that protects the calorimetric vessel with the pressure vessel from external temperature influences (7);

- temperature sensor or thermometer that measures the change in temperature in the calorimeter vessel (1)

- electric fuse with fusible wire and electrodes (6) for igniting the fuel in the sample cup (3) installed in the pressure vessel (4); and

- tube (2) for supplying oxygen O₂.

Due to the fact that during a combustion reaction in an oxygen atmosphere, a high pressure is created in a strong vessel for a short period of time, measurements can be dangerous and safety rules must be strictly observed. The calorimeter, its safety valves and ignition electrodes must be kept in good working order and clean. The weight of the sample must not exceed the maximum allowed for the given calorimeter.

Specific fuel consumption per unit of thrust is a measure of the efficiency of any engine that burns fuel to produce thrust. It is these engines that are installed on a reusable transport spaceship"Atlantis".

Do you find it difficult to translate units of measurement from one language to another? Colleagues are ready to help you. Post a question to TCTerms and within a few minutes you will receive an answer.

Specific voluminous ,

she is special voluminous heat of combustion of fuel,

she is special voluminous heating value of the fuel.

Specific voluminous

The calorific value of a fuel is the amount of heat

which is released during the complete combustion of a volumetric unit of fuel.

Online converter for translation

Translation (conversion)

fuel volumetric calorific value units

(calorific value per unit volume of fuel)

Mass (weight) specific calorific value is practically the same for all types of fuel of organic origin. And a kilogram of gasoline, and a kilogram of firewood, and a kilogram of coal - will give approximately the same amount of heat during their combustion.

Another thing - volumetric calorific value. Here, the calorific value of 1 liter of gasoline, 1 dm3 of firewood or 1 dm3 of coal will differ significantly. Therefore, it is the volumetric calorific value that is the most important characteristic substances, as a type or grade of fuel.

The transfer (conversion) of the volumetric calorific value of the fuel is used in heat engineering calculations according to a comparative economic or energy characteristic for different types fuel, or for different grades of the same type of fuel. Such calculations (for comparative characteristic for heterogeneous fuel) are needed when choosing it as a type or type of energy carrier for alternative heating and heating of buildings and premises. Since various regulatory and accompanying documentation for different grades and types of fuel often contains the value of the calorific value of the fuel in different volumetric and thermal units, then in the process of comparison, when reducing the value of the volumetric calorific value to a common denominator, errors or inaccuracies can easily creep in.

For example:

– The volumetric calorific value of natural gas is measured

in MJ/m3 or kcal/m3 (according to )

– The volumetric calorific value of firewood can be easily expressed

in kcal/dm3, Mcal/dm3 or in Gcal/m3

To compare thermal and economic efficiency of these two types of fuel it is necessary to bring it to a single unit of measurement of volumetric calorific value. And for this, just such an online calculator is needed.

Calculator Test:

1 MJ/m3 = 238.83 kcal/m3

1 kcal/m3 = 0.00419 MJ/m3

For online conversion (translation) of values:

– select the names of the converted values at the input and output

– enter the value of the quantity to be converted

The converter gives the accuracy - four decimal places. If, after conversion, only zeros are observed in the “Result” column, then you need to select a different dimension of the converted values or simply click on. For, it is impossible to convert a calorie into a Gigacalorie with an accuracy of four decimal places.

P.S.

Translation (conversion) of joules and calories per unit of volume is simple mathematics. However, driving a bunch of zeros overnight is very tiring. So I made this converter to unload the creative process.